Automotive Suspension Failures

by

Charles C. Roberts, Jr.

Automobile suspension systems are mechanical devices whose

function is to support the vehicle body and other components

above the wheels. There are a variety of designs including coil

spring, longitudinal leaf, transverse leaf, torsion bar, MacPherson,

Christy, and solid axle.

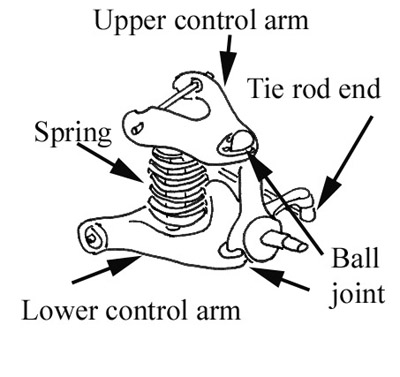

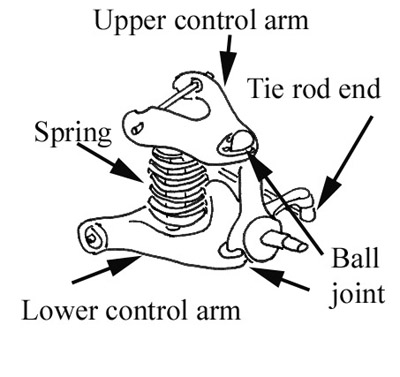

Figure 1 - MacPherson strut suspension

Figure 2 - Solid axle suspension

Figure 3 - Control arm suspension with coil springs

Figures 1 through 3 are drawings of typical

suspension systems found on most vehicles on the road. Figure 1 is

the classical MacPherson strut suspension, which is common on

many front drive vehicles. The strut, which is also a shock damper,

moves vertically while the control arm limits transverse and

longitudinal movement. The system is compact, efficient and

adapts easily to front and rear applications. Figure 2 is a view of an

earlier design: the solid axle suspension with king pin. The solid

axle beam is supported by springs and connects to a swiveling axle

via the king pin. This suspension is often used on heavier vehicles

such as trucks and on some older vehicles. Figure 3 depicts a

control arm suspension with coil springs. This independent

suspension system is used on many older and rear wheel drive

vehicles.

Automobile accident investigation may focus on a vehicle's

suspension system, being guided by evidence of possible

malfunction or statements from the insured driver or witnesses.

Automotive suspension failure can be caused by a design defect, a

manufacturing defect, poor maintenance or the accident.

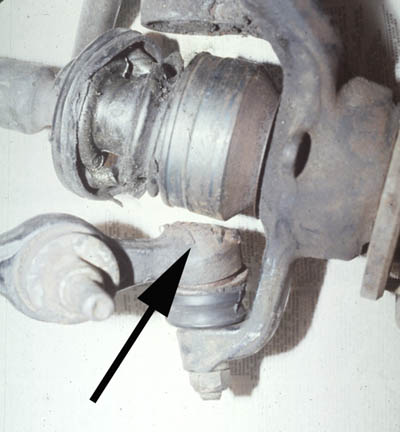

Figure 4

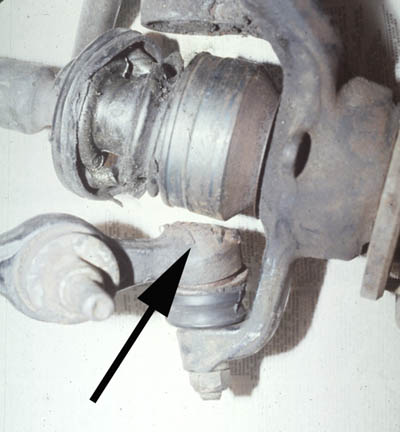

Figure 4 is a view of a MacPherson front suspension on the right

side of a compact car. Evidence suggests that the lower ball joint

(arrow) failed, causing the vehicle to steer uncontrollably, which

resulted in an accident. Figure 5 is a top view of the ball joint

showing wear patterns from the drive shaft rotor just above the ball

joint. The ball joint itself was dry and badly worn with no evidence

of lubrication. The vehicle had over 100,000 miles on the

odometer. The wear on the top of the ball joint suggests that for a

period of time, the joint had failed and had moved vertically and

rubbed against the axle rotor. The rotor was acting as a retainer of

the joint, preventing it from separating from the suspension. This

condition would result in excessive play in the steering, plus a loud

noise that should have acted as a warning to the insured driver that

a problem existed. The driver continued to operate the vehicle until

the accident occurred. The failure of the ball joint was determined

to be maintenance related with no evidence of a manufacturing

defect.

Figure 5

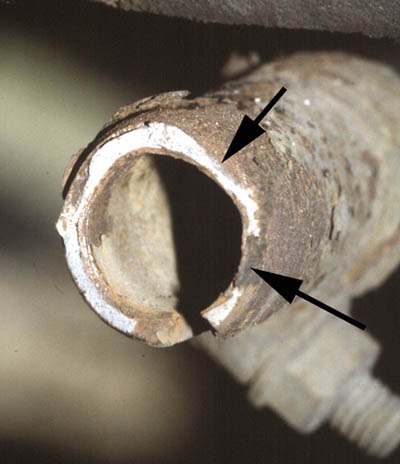

Figure 6

Figure 6 is a view of a king pin assembly from a large road tractor.

Figure 7 is a close-up of a crack in the king pin housing. A truck

driver claimed loss of control while on a winding rural highway.

Analysis of the housing fracture surface indicated that

environmentally assisted cracking had caused the failure. What

initiated the environmentally assisted cracking was severe wear

from lack of lubrication, a maintenance related failure.

Figure 7

Figure 8

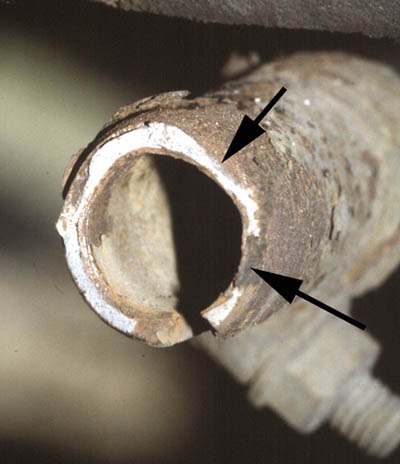

Figure 8 is a view of a front control arm suspension with a

fractured tie rod end. Figure 9 is a close-up of the fracture surface.

The driver indicated that the tie rod end suddenly failed, and an

accident resulted. The lower arrow in Figure 9 points to a corrosion

related crack that had formed through the tubing wall. Despite the

corrosion damage to the tubing, the fracture surface (white area,

upper arrow) is characteristic of a sudden overload, indicating that

a sudden failure under normal conditions was unlikely. The likely

cause would be an impact with a noncompliant object such as a

curb or another vehicle.

Figure 9

Figure 10

Figure 10 is a view of a rear control arm bolt in a late model front

drive automobile. The driver complained of loss of control, which

resulted in a vehicle rollover and personal injury. The right end of

the bolt had fractured. A close-up of the fracture surface is shown

in Figure 11.

Figure 11

Metallurgical analysis of the part revealed improper heat treating

of the bolt, which was the cause of the failure and was a

manufacturing defect. When the bolt failed, the right rear control

arm parted from the suspension, causing the right rear tire to point

outward at an angle. The ensuing yaw motion terminated with a

vehicle rollover.

Figure 12

Figure 12 depicts the right rear tire of a vehicle with a severe toe-in

of about 30 degrees. The body damage is characteristic of having

struck another vehicle. The control arm and tie rod end was badly

bent, but not fractured, suggesting that this condition was most

likely a result of the impact.

Suspension systems are often blamed as a cause of an accident.

Driver error can explain many of the accidents, while the

remaining ones can be attributed to poor maintenance, design or

manufacturing defects. Obviously, insurers are interested in causes

of failure that suggest negligent behavior by some other party for

subrogation purposes. If legal action is contemplated, then

potential litigants should be placed on notice as to the existence of

the evidence and a joint protocol developed before any destructive

testing is performed.

FOR TECHNICAL ARTICLES CONTACT CLAIMS MAGAZINE AND ASK

FOR A REPRINT OF A PAST TECHNICAL NOTEBOOK ARTICLE

CLAIMS MAGAZINE