SUMP PUMP FAILURES

By

Charles C. Roberts, Ph.D., P.E.

Sump

pump failures lead to substantial water losses and insurance claims that

require the attention of claims representatives. There are a variety of failure

modes associated with sump pumps, some covered by insurance, others not. Before

proceeding to discussing typical failure modes, a brief review of sump pump

system technology may be helpful.

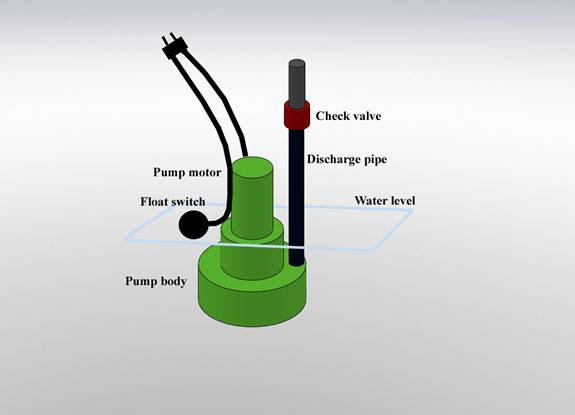

Figure 1A

Figure 1A depicts a typical

submersible sump pump system where the pump motor is in a waterproof enclosure and

designed to operate below water level. A float switch is used to control

operation and comes in a variety of designs, including the free floating type

(Figure 1A) as well as internal float or diaphragm designs. A check valve is

typically installed to reduce excessive cycling of the pump from back flow.

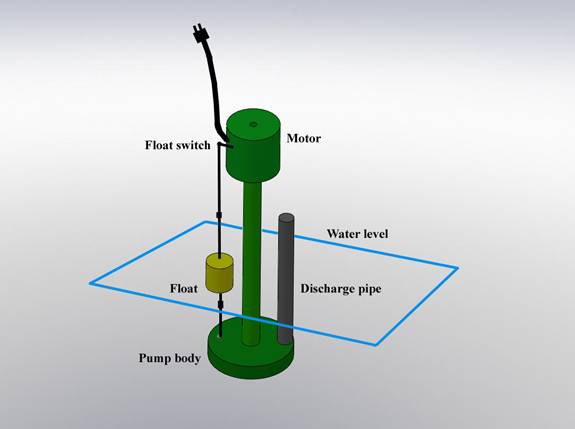

Figure 1B

Figure 1B shows a pedestal

sump pump where the electric motor must be above the water level, since it is

not in a waterproof enclosure. The float switch is at the motor and is usually

not waterproof. The discharge piping and check valve are the same as that of

the submersible sump pump. The pedestal and submersible sump pumps are the most

common.

Sump pumps fail to operate

for one or more of the following reasons:

1.

Power failure

2.

Improper

installation

3.

Improper or lack

of maintenance

4.

Wear out

5.

Defective

manufacture

The following is a review of

typical failure modes, taken from actual losses involving sump pumps. Power

failure is probably the most common cause of sump pump failure. Electrical

power outage without a battery or auxiliary generator back up, results in many

flooded basements. Occasionally, even back-up systems fail especially during

long term outages. Batteries loose capacity over time and may not be able to

power a pump for sufficient time during the power outage.

Figure 2

that supplying electricity to

the sump pump. Figure 2 shows a sump pump system that failed as a result of

branch circuit overloading, considered an improper installation. When a power

fluctuation occurs in such an overloaded circuit, the starting current, which

is often much higher than the steady state operating current, from the other

appliances as well as the sump pump will trip the breaker and render the sump

pump system inoperative. A dedicated

circuit for the sump pump is certainly recommended.

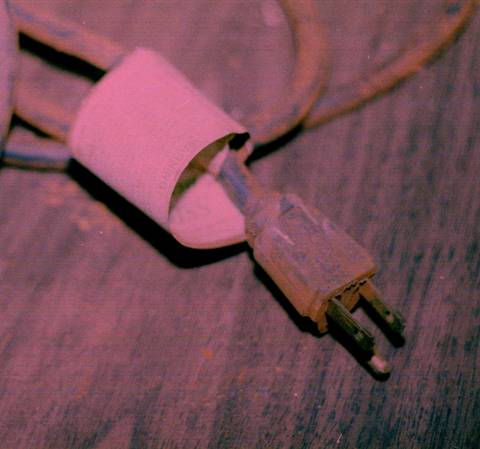

Figure 3 is a view of a sump

pump plug that was connected to an extension cord. Rust patterns on the plug

suggest that the connection was occasionally under water which caused the circuit

breaker to trip and sump pump failure, an improper installation. It is not

recommended to attach extension cords to sump pumps. Extension cords offer

increased electrical resistance, which can drop voltage and damage pump motors.

Also the connection (Figure 3) can fall into the sump, an electrical safety

hazard as well as a possible obstruction to normal pump operation.

Figure 3

Figure 4

Interference with mechanical

operation of the pump is another common cause of sump pump failure. Sump pits

with gravel bottoms are susceptible to this. Figure 4 shows a rock jammed in a

sump pump impeller, causing sump pump failure and a water loss. Interference of

the float switch also can cause sump pump failure. These are both maintenance

related causes of sump pump failure.

Figure 5

Internal failure of sump

pumps occur as a result of wear out or manufacturing defect. In Figure 5, a

winding failure in the single phase motor caused non operation of a new sump

pump, which was attributed to a manufacturing defect. There was premature

insulation breakdown on stator windings after a very short usage time, a

manufacturing defect in this case.

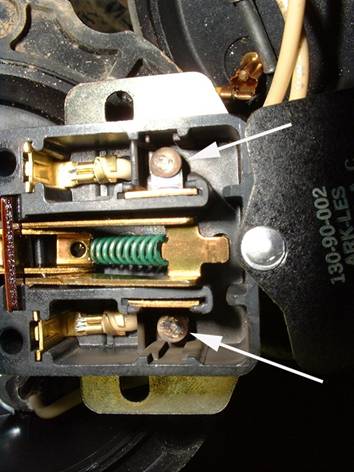

Figure 6

Figure 6 is a view of failed

contacts on the pump float switch. This particular case is a wear out failure

that was brought on by improper installation. Drain back of water, as the

result of a lack of a check valve in the system, caused excessive cycling of

the switch and premature failure of the switch. Early contact failure can also

be a result of a manufacturing defect such as improper plating or excessive

current draw by the motor. The expected life of a sump pump is approximately 10

years, but varies depending on operating hours and number of start/stop cycles.

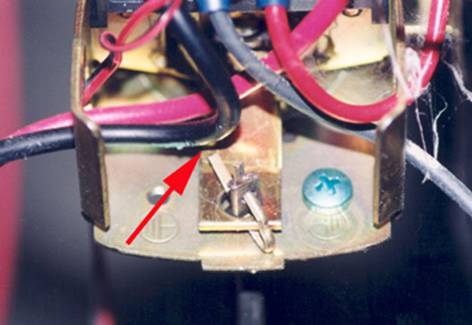

Figure 7

Figure 7 is an example of an

improper wiring job on a pedestal sump pump. What is depicted, is the float

switch wiring with the arrow pointing to chaffed insulation as a result of

interference with the float switch push rod. As the push rod rises to turn on

the switch, the push rod retainer clip chafed against the hot wire, which

shorted out, tripping the circuit breaker. The pump failed to operate during a

vacation period, flooding the finished basement.

Care should be taken in

handling pumps involved in basement water losses. Removal of the pump in order

to send it out for analysis may dislodge a rock (Figure 4) that caused a

malfunction. With the rock dislodged, the pump may operate properly. If the

pump must be removed and sent out for analysis, it is recommended that a

description of the system, along with photographs, accompany the pump to aid

the analyst in determining the probable cause of sump pump failure.