Figure 1

Figure 2

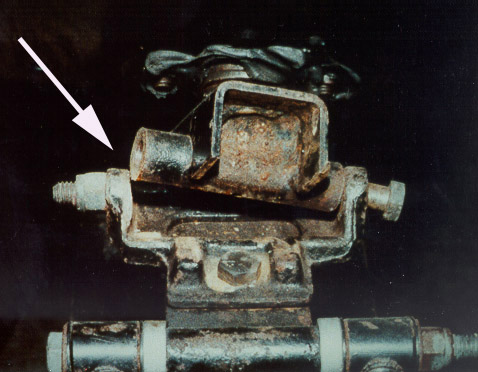

In Figure 2, a snowmobile steering ski bracket failed, causing

severe injury to the driver. The bolt had failed because of improper

bolt application.

Figure 3

In Figure 3, insufficient torque had been applied to an automotive

wheel stud, resulting in fretting of the wheel bolt hole area (black

deposit on the chrome wheel surface), failure of the wheel studs,

detachment of the wheel and an accident.

An important ingredient in the assessment of subrogation potential

from a bolt related accident is the recovery and preservation of the

failed bolt. In instances where the bolt fractured into two pieces,

recovery of both would be ideal, but one piece will show the

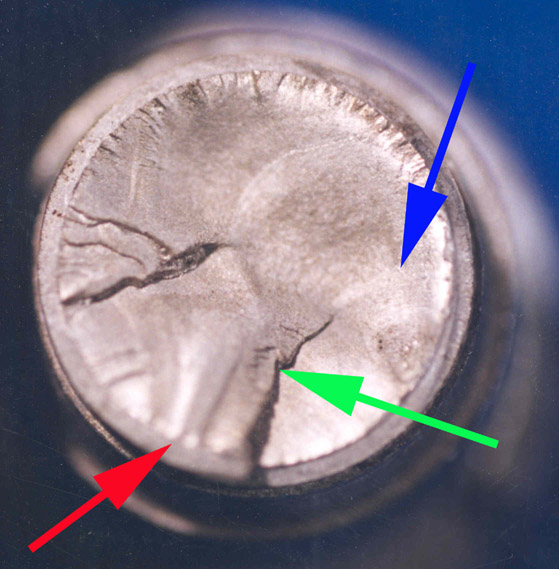

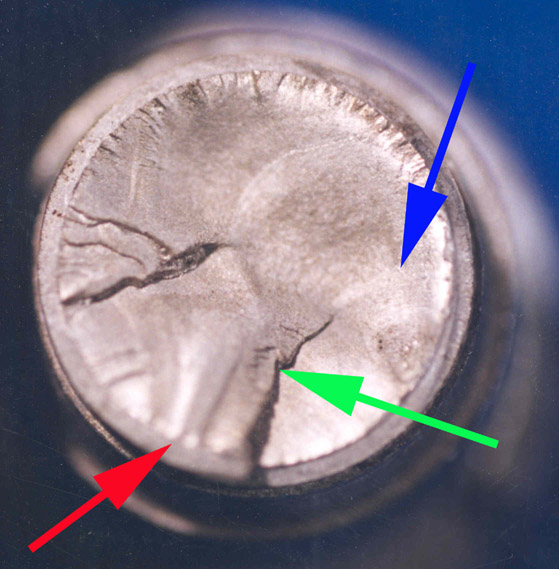

fracture surface which is the mirror image of the other. Figure 4 is

a typical bolt fracture surface showing a fracture origin area (red

arrow), ratchet mark (green arrow) indicating relatively high stress

or stress concentration and progression marks (blue arrow)

showing direction of crack advancement. These features are

utilized by the analyst to opine as to the probable cause of the

failure and should be preserved.

Figure 4

If subrogation is contemplated, then anticipating the action of the

respondent can help in planning an investigation. The typical

defense of choice is spoliation and a Daubert hearing long before

the merits of the case are discussed. Avoid the spoliation

argument with proper storage of the bolts and nuts. Each of the

individual failed bolt parts should be stored in separate packages to

avoid damage to fracture surfaces. Minimization of corrosion or

deterioration of the metallic surfaces during storage is

recommended. Get an agreement between parties as to a protocol

for nondestructive and destructive testing. Most microscopic

analysis is nondestructive but hardness testing, tensile testing and

chemical analysis are destructive. Avoid a Daubert hearing by

making sure that the failure analysis is performed in a scientifically

recognized manner with qualified analysts. Finally, the merits of a

bolt failure case may take several forms based on the failure

analysis and factual data. The bolt could be defectively

manufactured, defectively designed, improperly installed,

improperly torqued, or improperly selected for a particular

application.

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

Figure 3

In Figure 3, insufficient torque had been applied to an automotive wheel stud, resulting in fretting of the wheel bolt hole area (black deposit on the chrome wheel surface), failure of the wheel studs, detachment of the wheel and an accident. An important ingredient in the assessment of subrogation potential from a bolt related accident is the recovery and preservation of the failed bolt. In instances where the bolt fractured into two pieces, recovery of both would be ideal, but one piece will show the fracture surface which is the mirror image of the other. Figure 4 is a typical bolt fracture surface showing a fracture origin area (red arrow), ratchet mark (green arrow) indicating relatively high stress or stress concentration and progression marks (blue arrow) showing direction of crack advancement. These features are utilized by the analyst to opine as to the probable cause of the failure and should be preserved.

Figure 4

If subrogation is contemplated, then anticipating the action of the

respondent can help in planning an investigation. The typical

defense of choice is spoliation and a Daubert hearing long before

the merits of the case are discussed. Avoid the spoliation

argument with proper storage of the bolts and nuts. Each of the

individual failed bolt parts should be stored in separate packages to

avoid damage to fracture surfaces. Minimization of corrosion or

deterioration of the metallic surfaces during storage is

recommended. Get an agreement between parties as to a protocol

for nondestructive and destructive testing. Most microscopic

analysis is nondestructive but hardness testing, tensile testing and

chemical analysis are destructive. Avoid a Daubert hearing by

making sure that the failure analysis is performed in a scientifically

recognized manner with qualified analysts. Finally, the merits of a

bolt failure case may take several forms based on the failure

analysis and factual data. The bolt could be defectively

manufactured, defectively designed, improperly installed,

improperly torqued, or improperly selected for a particular

application.

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

WWW.CROBERTS.COM