SURFACES

It is generally considered in the industry that a walkway surface with a coefficient of friction higher than 0.5 is non-hazardous. (Ref 1). Federal regulations from the Americans with Disabilities Act recommend a coefficient of friction of 0.6 or higher. The coefficient of friction is a measure of the slipperiness of a surface. The lower the coefficient, the more slippery the surface. For instance, rubber on ice has a coefficient of friction around 0.06. The coefficient of friction for rubber on asphalt is approximately 0.6. Therefore, ice is about 10 times slipperier than asphalt. The coefficient of friction is the ratio of the weight of an object to the frictional force required to just move the object. If a block of concrete weighing 40 lbs. requires 20 lbs. to just start moving on a floor, the coefficient of friction is 20/40 or 0.5.

FIGURE 1

FIGURE 2

If a claim of a slippery surface arises, determination of the coefficient of friction through testing may help in the evaluation of the claim. Figure 1 is a view of a testing device called a slip meter. The slip meter measures the coefficient of static friction. The technician pulls on the meter with a string until the meter moves. The coefficient of friction is read directly on the meter. In Figure 1, the meter is being calibrated on a standard piece of tile. Once calibration is verified, the meter is placed on the floor to be measured, as shown in Figure 2. Three readings are made and averaged. The average coefficient of friction is compared to the particular standard being used, such as 0.5. If the readings are below 0.5, then the likelihood of a slippery surface having caused the accident has increased. If the coefficient of friction is greater than 0.5, then it is unlikely that a slippery surface is the cause of the accident. Figure 3 shows a test of a dance floor where a slip and fall accident occurred. The waxed floor had a coefficient of friction of between 0.6 to 0.7, which is acceptable. Some of the dancers would sprinkle “dance powder” under their tables and work the powder into their shoes. This is to aid in the sliding motion associated with dancing. The dance powder reduced the floor coefficient of friction to the range of 0.25 to 0.35, which is below the slip resistant range of 0.5, or greater, as defined in Reference 1. It is likely that the excessive use of the dance powder contributed to the slip and fall accident on the dance floor.

FIGURE 3

STAIRS

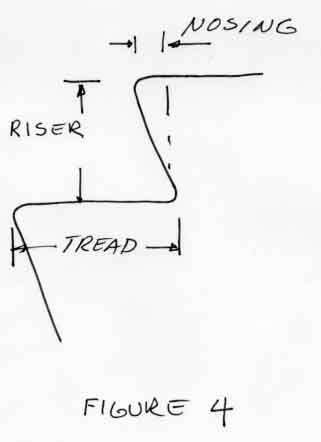

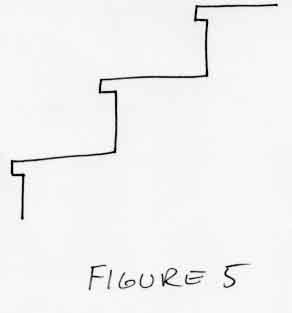

Slip and fall accidents often occur on stairs. Typical causes of accidents on stairs are slippery surfaces, stair construction or design deficiencies, poor lighting, obstructions on the stairs and inattentiveness. Reviews of human factors and architectural literature reveal that the optimum slope of a stairway for general purposes is approximately 30 degrees. This translates to a tread width of 11 inches and a riser height of about 6.5 inches (Figure 4). Reference 2 requires a minimum tread of 9 inches and maximum riser of 8.25 inches for single family dwellings. Many claims allege that the stairway was deficient and did not conform to code. In this case, dimensional measurement of the stairs is necessary to compare with building code requirements. Figure 4 shows a preferred stair design with smooth rounded nosing. A less preferred design is shown in Figure 5 where the abrupt transition from riser to nosing can increase the chance of tripping while ascending the stairs. Many older buildings, along with some new ones, have this type of stair design. Although not forbidden by code, the abrupt transition design is less desirable. Handrails are often required by code for stairways. Typically handrails should be between 30 and 34 inches above the nosing of the treads.

LIGHTING

Often, slip and fall claims involve poor lighting. Local building codes require a minimum lighting level often specified in foot-candles. For instance, the lighting level for a stairway should not be less than 3 foot candles at floor level as indicated in Reference 2. To verify the lighting condition at the accident scene, testing can be accomplished easily using a variety of meters as shown in Figure 6. Each of the meters is portable and displays the lighting level in an analog or digital readout. It is desirable to replicate the lighting conditions to match those at the time of the accident before taking a reading.

CLOSING

The above mentioned tests will reveal any deficiencies with respect to building construction that could have caused or contributed to the accident. If no deficiencies were found, analysis of medical records may be helpful. If the claimant was elderly, the fall may be a result of bone thinning (osteoporosis) rather than a deficiency in the building construction. Biomechanical analysis of bone fractures (see Claims, August 1994) may reveal a fracture mode that is not consistent with the accident scenario, which may be fraudulent. Chemical usage at the time of the accident may be significant. Finally, if the accident scene is found to be hazardous, were sufficient warnings posted.

REFERENCES

1. ASTM D2047-93, “Standard Test Method for Static Coefficient of Friction of Polish-Coated Surfaces as Measured by the James Machine”, American Society For Testing & Materials, West Conshohocken, Pennsylvania, 1993

2. BOCA Basic Building Code, Building Officials & Code Administrators International, Inc., Homewood, IL.

FOR TECHNICAL ARTICLES CONTACT CLAIMS MAGAZINE AND ASK

FOR A REPRINT OF A PAST TECHNICAL NOTEBOOK ARTICLE

CLAIMS MAGAZINE

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

WWW.CROBERTS.COM