SHINGLE CURLING

By

Charles C. Roberts, Jr. Ph.D., P.E.

Claims Magazine January 2011

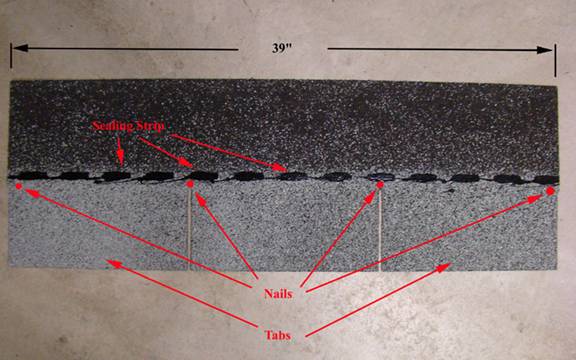

Figure 1 is a photo

of a typical glass fiber substrate asphalt shingle, a common roofing shingle

used throughout the

Figure 1

The following are

typical causes of shingle curling:

- The purpose of the sealing strip is to

hold the neighboring shingle tabs down to prevent curling or lift during

high winds. If the shingles are installed improperly where the sealing

strip does not line up with the next shingle according to the

manufacturer’s recommendation, then the shingle tabs will not be secure

and will curl upward or inward over time.

Figure 2

Figure 3

- Improper nailing is a common cause of

shingle curl. In Figure 1, the nails are placed according to the shingle

manufacturer’s recommendations. In Figure 4, a nail has been driven into

the sealing strip which limits the effectiveness of the seal on the

sealing strip. Over time, as a result of thermal cycles (heating during

the day and cooling at night) the nail can back out, causing the shingle

tab to lift and part from the seal, causing curling as shown in Figures 4

and 5. Also, insufficient nailing can lead to curling.

Figure 4

Figure 5

- A lack of

attic space ventilation is another cause of shingle curl. Moisture evolves

in the attic as a result of moisture generation in the home and from the

outside environment. Normally, moisture laden air in a well ventilated

attic will be swept away by air flow and not cause a problem. In poorly

ventilated attics, water vapor will increase and water will eventually

condense on the roof sheathing. As the sheathing becomes moisture laden, shingle

curling can occur. A lack of attic space ventilation can also cause high

attic temperatures which can reduce the effectiveness of the sealing strip

adhesive, causing curling over time. Most building codes require at least

one square foot of free air opening for every 150 square feet of attic

area. In homes with an acceptable vapor retarder,

300 square feet of attic space is allowed per one square foot of open

ventilation area. Of course, attic ventilation openings should be

distributed so that approximately 50% of the open area is at the ridge and

approximately 50% at the soffits.

- Product defects are also a possible

cause of shingle curling. Inadequate adhesion of bituminous coating and

grit, poor quality substrate, deterioration rates higher than that put

forth in warranties and inadequate sealing strip are all problems

associated with defective manufacture. The recent evolution of class action

suits against CertainTeed regarding premature

failure of organic substrate shingles is an example of premature

degradation of shingles. Figures 6a & 6b are photographs of 25 year

warranty, CertainTeed shingles, 9 years after installation. There is evidence of inward

curling and loss of granules from cracking of the cardboard substrate,

which easily deteriorates in normal weather related conditions.

Figure 6a

Figure 6b

In conclusion, fractured

shingle tabs can be related to wind damage, however curling of shingles is a

long term problem associated with lack of ventilation, improper installation or

product associated defects.