SNOWPLOWS CAN CAUSE VEHICLE FIRES

By

Charles C. Roberts, jr.

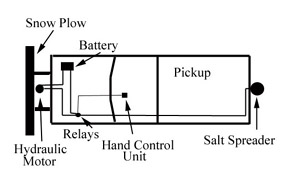

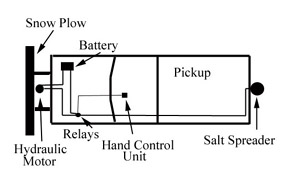

Snowplows and other snow removal related

equipment are often installed as after-market

additions to vehicles such as light trucks and some

sports utility vehicles. Figure 1 is a typical

conceptual drawing of how most of the snowplow

kits are put together. The snowplow is mounted at

the front frame area and houses a hydraulic motor

and system to raise, lower and adjust the plow

angle. Power wiring for the hydraulic motor and

other accessories, like a salt spreader, are controlled

via a relay system that is connected to the hand

control in the vehicle cab. The hand control is

connected to the hydraulic motor control and salt

spreader control systems, using typical light gauge

service wiring.

Figure 1

Installers of this equipment range from the

professional to the "first timers." Professional

installations usually work out well, while those

installed by "part-timers" can be deficient. One of

the most common problems with after-market

snowplow installations is routing of electrical

cables. After the apparatus has been mounted to the

vehicle frame, little attention is paid to proper

location and attachment of snowplow system related

electrical wiring. Typical installation errors include:

improper securing of the wiring, resulting in

chaffing; wires contacting hot or rotating surfaces;

and wires wound across sharp metal structures that

penetrate the insulation and cause short circuits.

Figure 2

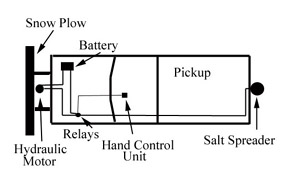

Figure 2 is a view of a vehicle that sustained a fire

in the engine compartment near battery wiring.

Figure 3 is a view of the salt spreader wire that had

been routed through the frame area to the back of

the vehicle. The wire was loose in the vicinity of the

exhaust pipe and was periodically in contact with

the exhaust pipe. This resulted in an electrical short

circuit that overloaded the battery and caused an

engine compartment fire.

Figure 3

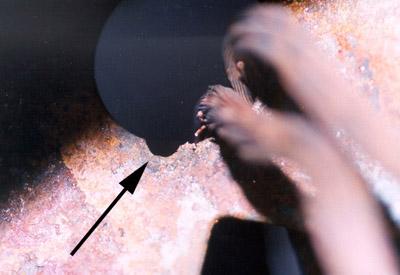

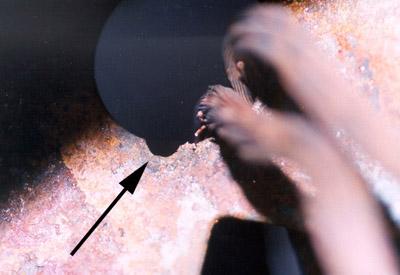

Figure 4

Figure 4 is a typical after-market snowplow

assembly that is mounted to the vehicle frame. A

common mistake by installers is to pass electrical

wires through holes in the vehicle frame without

adding chafing protection such as using a rubber

grommet. Figure 5 shows such an installation

through a hole in the front body work of the vehicle.

The arrow points to electrical arc eroded metal

where a cut in the wire

Figure 5

Figure 6

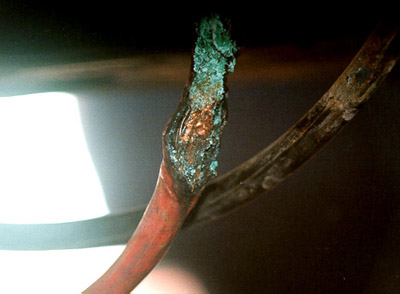

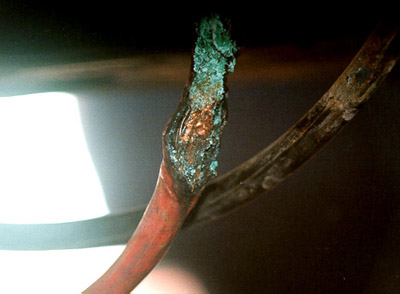

insulation most likely occurred. Figure 6 shows an

arc bead of copper in the area of the wire that

shorted. The arc bead forms at high temperatures

generated during the electrical fault, which in this

case caused an engine compartment fire in the

vehicle. Figure 7 is a view of a loose electrical

power cable that was not properly secured to a cable

clamp. It shorted as a result of chaffing and was

welded to the wheel well as shown in the close-up

of Figure 8. The heat from the short circuit caused a

fire in the engine compartment and total loss of the

vehicle.

Figure7

Figure 8

When investigating the cause of a fire in a

snowplow equipped vehicle, an inspection of the

snowplow installation may yield evidence as to

cause. Since these devices may be installed by

unknowledgeable installers, they are prone to

failures resulting from poor workmanship.