FIRE LOSS FROM IMPROPER HALOGEN FLOODLIGHT

INSTALLATION

By

Charles C. Roberts

Halogen floodlights have been used in both residential and

industrial applications for years. They are characterized by high

light intensity on task and high heat dissipation.

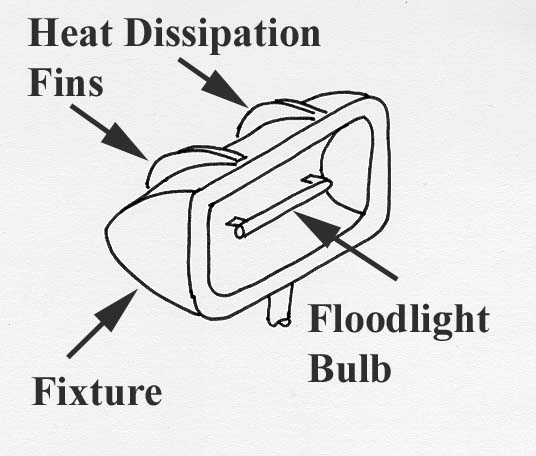

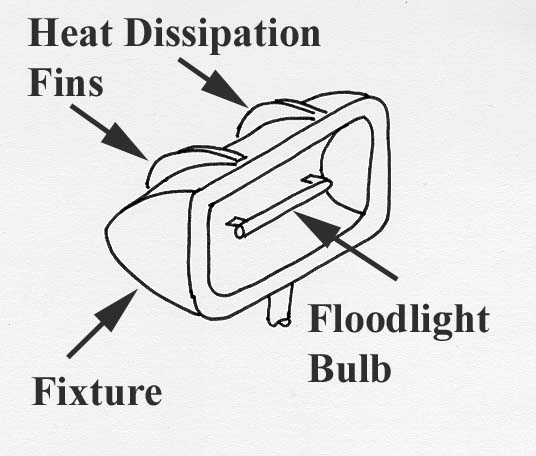

Figure 1

Figure 1 is a drawing of a typical halogen light fixture. The fixture

frame supports a receptacle for a cylindrical halogen bulb, which is

protected from the weather by a lens and seal. The bulbs are very

warm, and cooling fins are usually molded into the back of the

fixture to help dissipate the heat. Most manufactures warn against

placing these fixtures too close to combustible materials because of

the obvious fire hazard, which leads us to the subject matter of this

article.

Figure 2

Figure 2 is a large feed storage facility that was badly damaged by

a fire that nearly consumed the roof. The arrow points to a fire

origin at an eave in the vicinity of newly installed flood light

fixtures. The fixture at the origin was badly damaged. Figure 3 is a

view of another light fixture that had been installed in the storage

area. There were no other ignition sources in the area, other than

the electrical fixtures, since the building was not heated. The

fixtures were mounted in an unusual way.

Figure 3

Figure 4

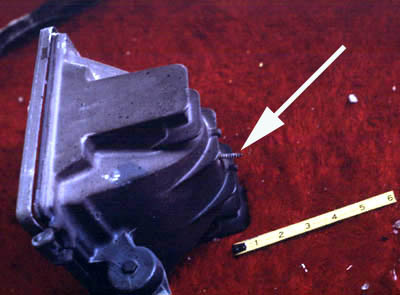

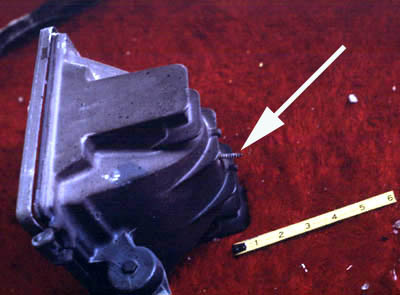

Figure 4 shows one of the unburned fixtures removed for

inspection. A hole had been drilled in the back of the halogen flood

lamp heat sink and a screw inserted to secure the fixture to the

wood structure near the eaves.

Figure 5

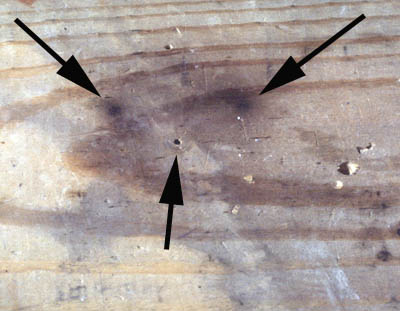

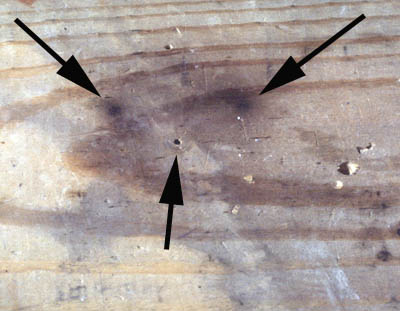

Figure 5 shows the wood joist where the fixture had been mounted.

The middle arrow is the screw hole while the two dark areas (left

and right arrows) are parts of the heat sink that had pressed against

the wood. The dark regions are advanced stages of pyrolysis:

indicating that significant heating of the wood has occurred, drying

it out, reducing ignition temperature and creating conditions for

ignition. Inquiry as to the reason for the unusual mounting method

of the lighting fixtures resulted in the following explanation. The

lighting had been installed with proper clearance between the

fixture and wood at a lower level on the wall by an electrical

contractor. Several fixtures had been damaged by piles of feed that

were being pushed up against the wall as shown in Figure 6. In

order to eliminate the problem, the fixtures were moved by the

facility’s maintenance people, to a location higher on the wall and

secured using a wood screw in an attempt to make a sturdier

fixture mount.

Figure 6

Figure 7

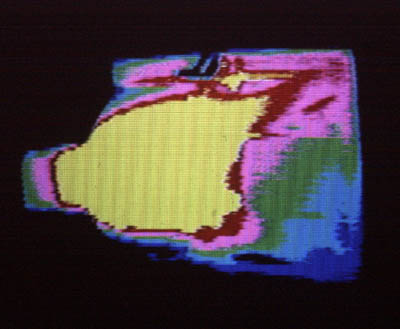

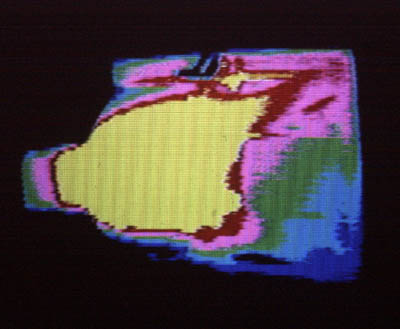

Figure 7 shows the back heat sink area of the fixture. Figure 8 is an

infrared thermogram showing significant heating of the heat sink

on the back of the fixture. The rear heat sink is the hottest surface

on the fixture and was attached to a wood structural member using

a wood screw. Apparently, one of the fixtures eventually ignited

the wood joist and adjoining roof structure, resulting in the loss. It

should be noted that pushing the feed up around the fixture as

shown in Figure 6 aggravates this condition by reducing heat

transfer from the fixture.

Figure 8

Most manufacturers of halogen flood lamps warn about the fire

hazards of insufficient clearance between the fixture and

combustible materials. Ignoring these recommendations can

precipitate a significant fire loss as illustrated by this field

expedient.