WATER PIPE LEAKAGE FROM EROSION-CORROSION

By

Charles C. Roberts, Jr., Ph.D., P.E.

Upon returning from a 2 week vacation, the insured discovered multiple leaks in copper water pipes throughout the home. The insured recounted that he had had minor leaks in the copper water pipes over the previous 6 months, but none serious enough to submit a claim. Unfortunately, with no one home and no water alarm system, the basement filled with water during the vacation, causing a substantial loss. Multiple leaks in a relatively new copper water piping system is certainly unexpected.

Figure 1

Figure 1 is a view of part of the insuredís piping installation. Copper piping delivers hot water to the multi zoned heating system using circulating pumps modulated by zone control valves. †

Figure 2

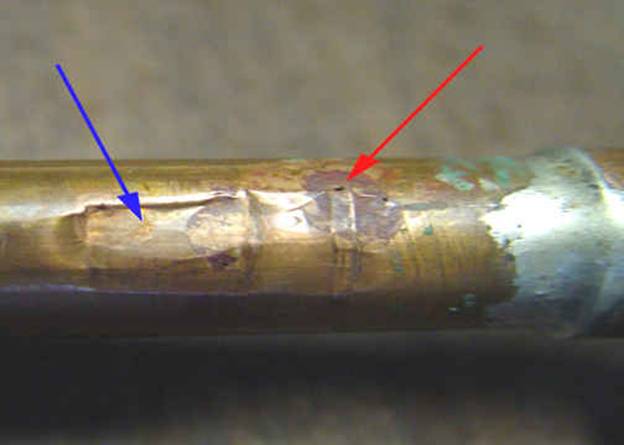

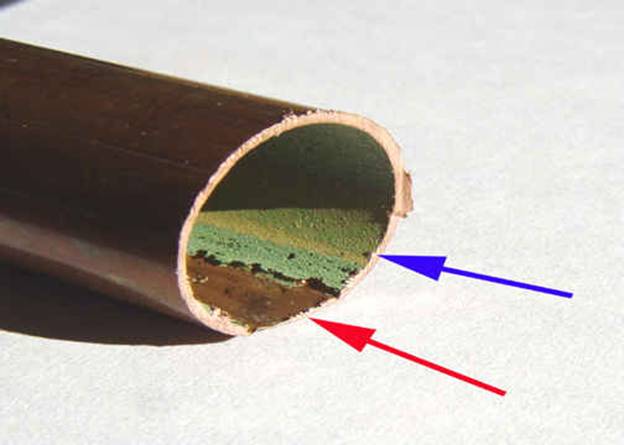

Figure 2 shows a typical leak in the insuredís 4 year old piping system. The red arrow points to pin holes in the pipe wall. Notice the crushed pipe wall which is much thinner than normal (blue arrow). Figure 3 is a view of a section of the failed pipe showing the interior surfaces. The blue arrow in Figure 3 points to the normal wall thickness of the copper tubing, while the red arrow points to an excessively thin wall area where pin hole leaks had occurred. This thinning of the copper pipe wall in new installations is characteristic of the phenomenon called erosion-corrosion. †Due to turbulence and excessive water velocity, the passive corrosion protective film has been removed in some areas, causing accelerated corrosion of the pipe wall, thinning of the pipe wall and eventual water leakage.

Figure 3

Figure 4

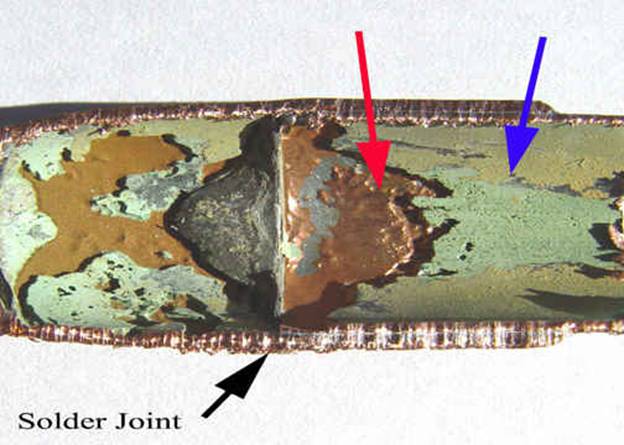

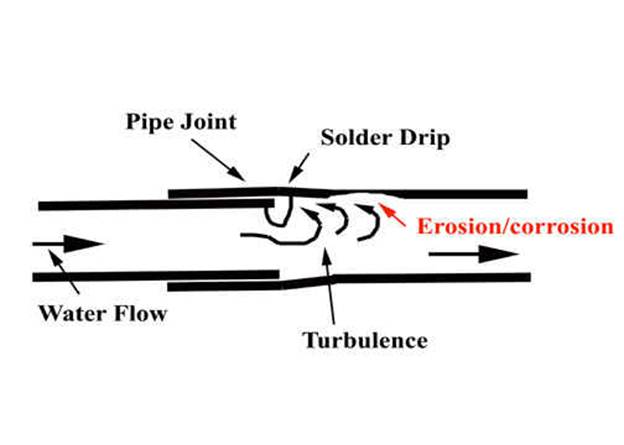

Figure 4 is an example of turbulence induced erosion-corrosion near a solder joint as indicated by the black arrow. The blue arrow shows the passive film protecting the copper pipe. The red arrows points to the eroded pipe material caused by high water velocity due to water turbulence, as the water flows from left to right in the photo. In each of these cases, the water leakage occurred suddenly and without warning, as there is no external sign of this problem. Figure 5 shows the turbulence mechanism of erosion/corrosion that was observed in Figure 4.† The turbulent flow of water increases velocity near the pipe surface, wiping clean the passive protective film and accelerating the corrosion mechanism.

Figure 5

Typically, copper piping is chosen because of its long life expectancy of at least 20 years. So why does such a failure occur early in the life of the piping?† The root cause, excessive water velocity near the pipe surfaces, can be a result of either water system design, construction or both. It is often purported that the water velocity should be in the range of 4-5 feet per second. This is governed by the piping system design. For a given flow rate, a larger diameter pipe will reduce water velocity, while a smaller diameter pipe will increase water velocity.† Pipe joints and bends in piping offer the highest probability of excessive water velocity and erosion-corrosion, which should be accounted for in system design. Along with improper design, improper workmanship can also be a cause of this failure mode. Ragged pipe joints, with excessive solder dripping, causes excessive turbulence, leading to erosion-corrosion of the metal.

The ingredient in erosion-corrosion related water leakage is a sudden unexpected event, on a relatively new piping system that has many bends and sections of small diameter tubing. For those examining such claims, the water system designer as well as installer are potential subrogation targets.†

Published in Subrogator Magazine