DUMP TRAILER ROLLOVER ACCIDENTS

By

Charles C. Roberts, Jr.

Dump trailers are semi-trailers with a dump box mounted on a

frame, equipped with a hoist cylinder to raise and lower the box.

These vehicles haul a variety of materials ranging from gravel to

manufactured granular products. Dump trailers come in a variety

of lengths with the longer vehicles being susceptible to instability

and rollover. Figure 1 shows a dump trailer that rolled over while

the hoist cylinder was fully extended and the vehicle was dumping

a load.

Figure 1

Figure 2 is a view of the accident scene. The vehicle was

unloading on slightly sloped ground. Most operator manuals for

dump trailers caution about making sure the load is dumped on

level ground because the extension of a long box into the air can be

hazardous with even the smallest degree of tilt to the chassis.

Figure 2

Figure 3

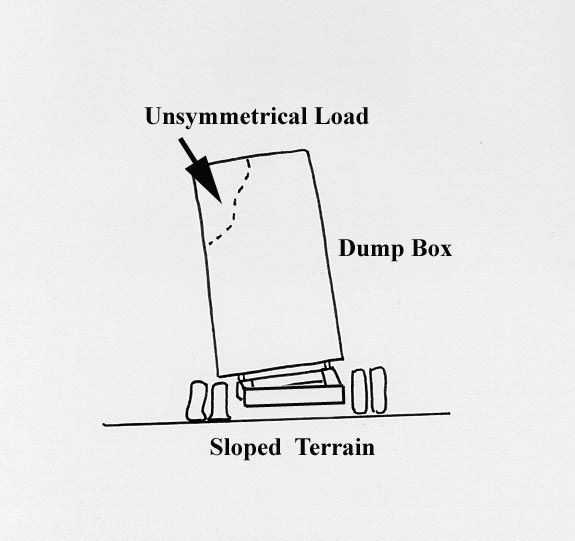

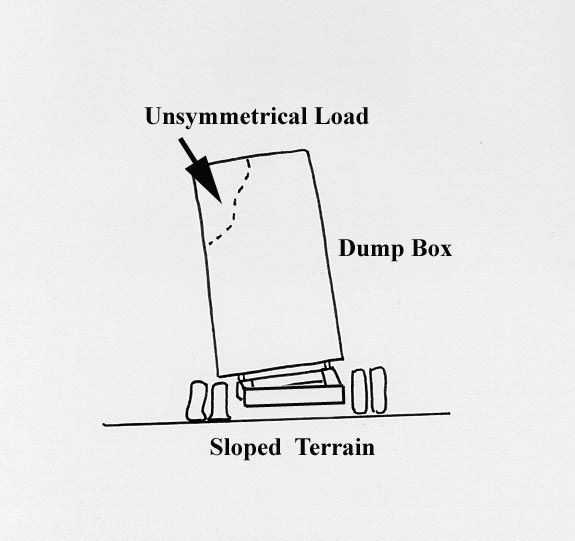

What had apparently happened in this accident is depicted in

Figure 3. The dump trailer was being unloaded on sloped terrain

that made the dump box tilt to the left as shown in the drawing.

According to a witness, part of the load adhered to the trailer bed

and remained on one side of the dump box, causing an

unsymmetrical load and more trailer tilt to the left. The

combination of sloped terrain and the unsymmetrical load was

sufficient to cause the trailer to roll to the left, causing severe

frame and hoist cylinder damage, rendering the vehicle a total loss.

The box was equipped with a vibrator used to dislodge such

unsymmetrical loads, but it was not operable at the time.

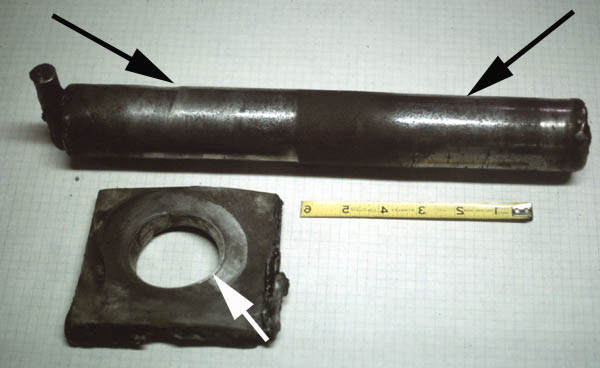

Figure 4

Figure 4 shows another loss where a dump trailer rolled over on

level ground, while dumping a load. Before the vibrator could be

used, the vehicle suddenly rolled over, causing severe frame and

hoist cylinder damage. Inspection of the vehicle revealed severe

wear of the hoist cylinder support pin as shown by the arrow in

Figure 5. The bore where the pin was inserted, as well as the pin,

were badly worn, allowing the hoist cylinder to wobble laterally.

Figure 5

Figure 6

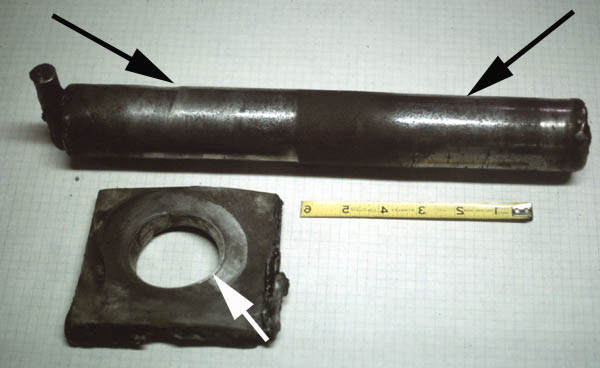

Arrows in Figure 6 shows severely worn areas on the pin as well as

the pin support plate.

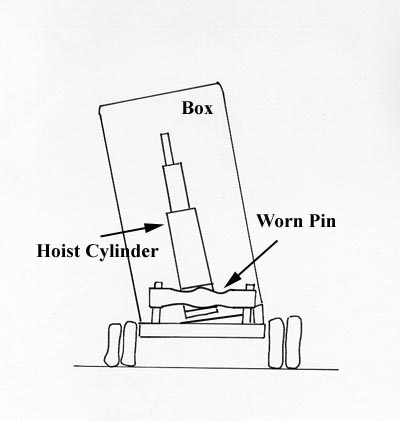

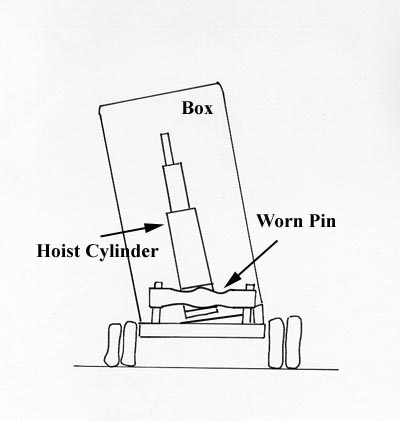

Figure 7 depicts the likely failure scenario, resulting in the

accident. Since the hoist cylinder support pin is badly worn, the

lateral stability of the base of the hoist is poor or non existent. The

hoist cylinder could extend in a variety of directions laterally,

causing the box to twist on the frame, especially when an

unsymmetrical load was encountered. As the hoist cylinder

extended, more lateral imbalance occurred until the frame twist

was sufficient to cause rollover. This accident can be attributed to

poor maintenance of the hoist cylinder mounting pin components.

Figure 7

When investigating dump trailer rollovers, the following

information is helpful. Get witness statements, which can help

establish the location and nature of the unloading process. Did the

driver use the mechanical vibrator to dislodge the load? Was the

material being dumped stuck to the dump box in an unsymmetrical

fashion that could cause a rollover? Was the unloading site level?

Did the truck driver attempt to drive away with the dump box fully

extended? Was the dump trailer in good working order? These

questions can help determine the cause of dump trailer rollovers,

which can result in significant damage to the vehicle - often a total

loss.