Figure 1

Figure 1 is a photo of a vehicle that was at the ori-

gin of a fire in a garage that was badly damaged and

a relatively large property loss. Burn patterns (1.)

traced the fire origin to the alternator shown in Fig-

ure 2. There was unusually severe melting of the al-

ternator housing near the rectifier unit, suggesting

that an electrical malfunction had occurred in the al-

ternator, causing the fire. Since the vehicle was

parked and had cooled down, other potential causes

of the fire were eliminated. The original alternator

had recently been replaced with a rebuilt alternator

by a garage mechanic near the insuredís home.

Figure 2

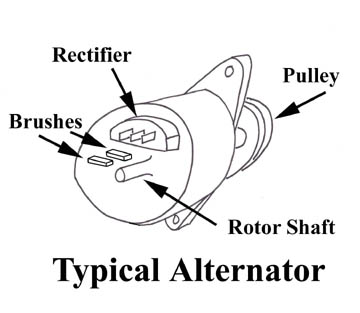

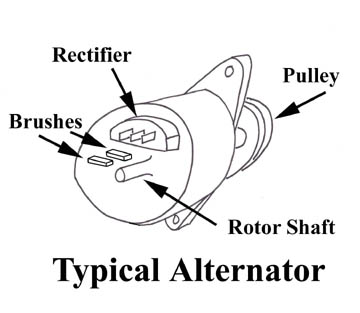

Figure 3 is a simplified drawing of a typical auto-

mobile alternator. The engine turns a belt driven

pulley, which turns the rotor shaft supplying electri-

cal energy to the battery and other electrical com-

ponents. The brushes, which transfer electricity

from the rotor shaft, wear over time and are re-

placed during rebuilding of the alternator. The recti-

fier, an electronic component, converts the alternat-

ing current to direct current and is a part that is of-

ten replaced during rebuilding.

Figure 3

Detailed inspection of the alternator yielded evi-

dence that the fire started in the rectifier assembly.

According to the rebuilder, the rectifier assembly

was replaced with an aftermarket unit as part of the

remanufacturing operation. The aftermarket rectifier

did not conform to the original equipment manufac-

turerís specification. In fact, it was discovered that

the rebuilder was not authorized to refurbish alter-

nators by the original equipment manufacturer. The

rebuilder did not perform any reliability testing or

sampling of the product for quality control pur-

poses. The rebuilder merely reverse engineered the

rectifier assembly by matching an off the shelf unit

with the expected output of an original equipment

manufactured rectifier.

Typically, original equipment manufacturers au-

thorize rebuilding of automotive components as

long as certain specifications are met. Specifications

include reliability testing, performance testing and

sample testing of a certain percentage of rebuilt

units. If a rebuilder remanufactures product with-

out following original equipment manufacturerís

specifications and without any alternative reliability

testing, then there is a high probability that the reli-

ability of the unit will be substandard. The particu-

lar rebuilder of the alternator in Figure 2 had ex-

perienced a very high premature failure rate with

customers.

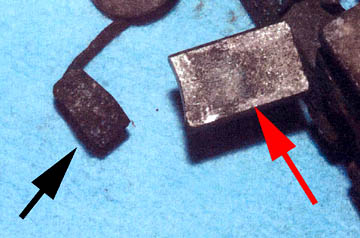

Figure 4

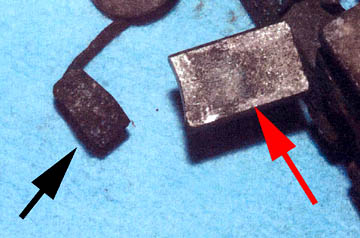

Additional inspection of the alternator revealed an

improperly assembled brush as shown in Figure 4.

The right (red) arrow points to an alternator brush

that was in good condition. The left arrow (black) is

the other brush that was sheared in half, a result of

improper assembly of the alternator. Although this

defect did not directly cause the fire, the alternator

would have failed much earlier than expected. This

attested to the degree of substandard workmanship

performed by the alternator rebuilder. It is apparent

in this particular case that the reverse engineering of

the rectifier assembly was substandard and lead to

the malfunction that caused the loss. The alternator

rebuilder eventually settled with the insurer of the

automobile and garage.

1. ďAutomotive Vehicle Fire Analysis,Ē Charles C.

Roberts, Jr. Ph.D., P.E., Roberts Publishing,

2004.

FOR TECHNICAL ARTICLES CONTACT CLAIMS MAGAZINE AND ASK

FOR A REPRINT OF A PAST TECHNICAL NOTEBOOK ARTICLE

CLAIMS MAGAZINE

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

Figure 2

Figure 3

Detailed inspection of the alternator yielded evi-

dence that the fire started in the rectifier assembly.

According to the rebuilder, the rectifier assembly

was replaced with an aftermarket unit as part of the

remanufacturing operation. The aftermarket rectifier

did not conform to the original equipment manufac-

turerís specification. In fact, it was discovered that

the rebuilder was not authorized to refurbish alter-

nators by the original equipment manufacturer. The

rebuilder did not perform any reliability testing or

sampling of the product for quality control pur-

poses. The rebuilder merely reverse engineered the

rectifier assembly by matching an off the shelf unit

with the expected output of an original equipment

manufactured rectifier.

Typically, original equipment manufacturers au-

thorize rebuilding of automotive components as

long as certain specifications are met. Specifications

include reliability testing, performance testing and

sample testing of a certain percentage of rebuilt

units. If a rebuilder remanufactures product with-

out following original equipment manufacturerís

specifications and without any alternative reliability

testing, then there is a high probability that the reli-

ability of the unit will be substandard. The particu-

lar rebuilder of the alternator in Figure 2 had ex-

perienced a very high premature failure rate with

customers.

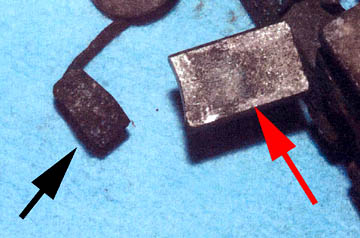

Figure 4

Additional inspection of the alternator revealed an

improperly assembled brush as shown in Figure 4.

The right (red) arrow points to an alternator brush

that was in good condition. The left arrow (black) is

the other brush that was sheared in half, a result of

improper assembly of the alternator. Although this

defect did not directly cause the fire, the alternator

would have failed much earlier than expected. This

attested to the degree of substandard workmanship

performed by the alternator rebuilder. It is apparent

in this particular case that the reverse engineering of

the rectifier assembly was substandard and lead to

the malfunction that caused the loss. The alternator

rebuilder eventually settled with the insurer of the

automobile and garage.

1. ďAutomotive Vehicle Fire Analysis,Ē Charles C.

Roberts, Jr. Ph.D., P.E., Roberts Publishing,

2004.

FOR TECHNICAL ARTICLES CONTACT CLAIMS MAGAZINE AND ASK

FOR A REPRINT OF A PAST TECHNICAL NOTEBOOK ARTICLE

CLAIMS MAGAZINE

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

Figure 4

1. ďAutomotive Vehicle Fire Analysis,Ē Charles C. Roberts, Jr. Ph.D., P.E., Roberts Publishing, 2004.

FOR TECHNICAL ARTICLES CONTACT CLAIMS MAGAZINE AND ASK

FOR A REPRINT OF A PAST TECHNICAL NOTEBOOK ARTICLE

CLAIMS MAGAZINE

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

WWW.CROBERTS.COM