THROTTLE MECHANISM FAILURE ANALYSIS

By

Charles C. Roberts, Jr., Ph. D., P.E

Statements by an insured that the accelerator pedal stuck and

caused an automobile accident are not unusual. Although many

such claims are unfounded, some do, indeed, have technical merit.

In one instance, an insured was driving a van when the accelerator

pedal did not return to the closed throttle position. Repeated “jabs”

to the pedal did not rectify the condition. The claimant then

jumped from the vehicle, which, apparently, did not cause serious

injury. The vehicle continued forward, starting to turn slowly in a

circle, traveling over curbs and a vacant field. The serious injury to

the claimant occurred when the vehicle circled back and ran over

the claimant. Witnesses indicated that the vehicle was traveling

about 20 mph - attesting to the theory that the vehicle throttle was

at least partially open. The vehicle was inspected and disassembled

in the presence of interested parties. During the inspection, it was

noted that the throttle was about 1/3 open and did not return to the

closed position. There were no obstructions that could have

prevented the return, other than some problem in the throttle

linkage system. The throttle body and throttle cable were removed

for inspection.

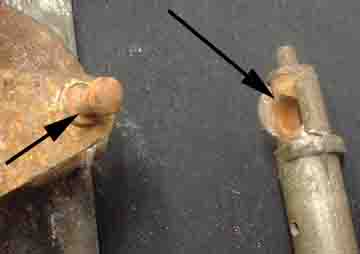

Figure 1

Figure 1 is a close-up of the throttle bellcrank and throttle cable

assembly. The right arrow is the throttle cable assembly.The left

arrow is the bellcrank that operates the throttle plates, controlling

engine speed. The throttle cable attachment point on the bell crank

would not swivel as originally designed. Figure 2 is a view of the

system with the throttle cable assembly removed.

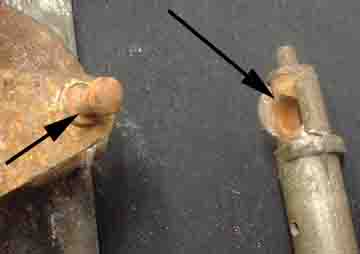

Figure 2

In Figure 2 the left arrow points to the bell crank ball stud. The

right arrow points to the cable attachment point. Severe corrosion

was found in the ball joint cavity. Apparently, the ball stud

corrosion did not allow free movement of the ball joint

mechanism, resulting in the accelerator system not returning to the

closed throttle condition. The corrosion induced failure mode of

this system resulted in intermittent failure to return to the closed

position. The stickiness of the accelerator could vary depending on

time of year, corrosion rate and vehicle usage. The vehicle

involved was about 6 years old. Typically, joints of this type are

maintenance free for the life of the vehicle. In this case, there

appeared to be either a manufacturing or design, corrosion-related,

deficiency that caused premature accelerator linkage failure.