WATER PIPE FAILURE:

Improper Plumbing Construction

by

Charles C. Roberts, Jr., Ph.D., P.E.

Insurance adjusters are often

faced with a large loss caused by water leakage from plumbing systems.

Investigating the cause is an integral part of the claims adjustment process

since it bears on insurance coverage as well as potential subrogation. The

first step is finding the source and determining the nature of the leak. Was

this a result of some manipulation of valves, either intentional or

unintentional or perhaps a failure of the pipe system. Photographing the leakage source and

documenting the circumstances of the leakage is helpful for those who will be performing

a more detailed analysis of the problem.

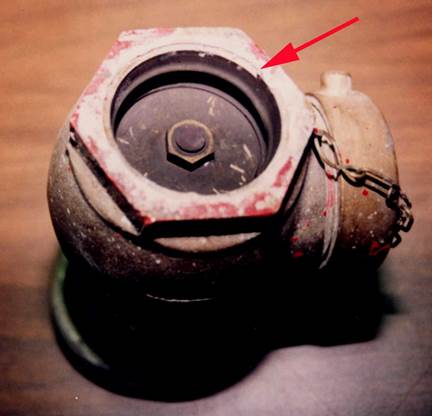

The following case study

serves to illustrate a water leakage loss as a result of a failed pipe. Figure

1 shows a water valve that became detached from a 2.5 inch pipe, causing

flooding of lower floors of a high rise building and a multi-million dollar

loss. The pipe failed in the threaded section as shown in Figure 2 (arrow).

Figure 1

Figure 2

Figure 3

Since there is potential

subrogation against the plumbing contractor and other parties, they should be

placed on notice in order to have a chance to inspect the scene prior to

repair. After the inspection by the plumbing contractor and other potential

litigants, the evidence should be removed for future detailed examination of

the components.

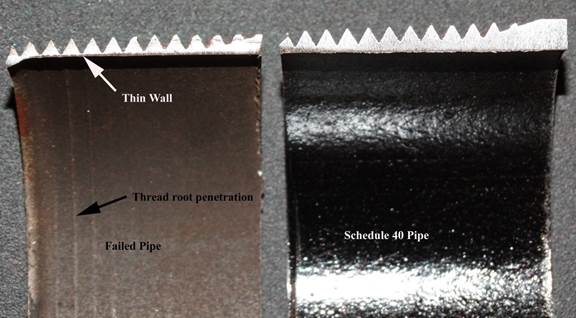

The photo of Figure 3 (left pipe section) was taken during the examination of the threaded section of the failed pipe. The threads on the failed pipe appear very deep, almost penetrating the pipe cross section. The lines, as indicated by the thread root penetration, are deformations of the pipe by the thread die, forming the root of the thread. Measurements of this pipe showed it to be American National Standard Institute (ANSI) Schedule 10 pipe. The pipe thread used was an American National Standard pipe thread. The pipe at the right in Figure 3 is Schedule 40 pipe with the appropriate standard tapered pipe thread. It is known in the plumbing industry that Schedule 10 pipe cannot be threaded because the pipe wall thickness is too thin. Typically, a rolled groove coupling system is one method of joining Schedule 10 pipe with other components. In this particular case, the pipe wall thickness was reduced significantly by the improper threading. Over time, water pressure variations caused failure of the pipe due to the thin and weakened wall cross-section. The root cause of the loss is improper plumbing construction and installation. Retention of evidence (valve, failed pipe section), taking statements of building personnel and documenting the circumstances will aid in a successful recovery for the insurance adjuster’s client.

Published in Claims March 2015

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM