STRUCTURAL

FAILURE IN SEMI-TRAILERS

FROM

OVERLOADING

By

Charles C.

Roberts, Jr., Ph.D., P.E.

Improper weight distribution can be a cause of structural failure in semi trailers. This can not only lead to the loss of the trailer, but also to the loss of cargo or even the possibility of an accident. The following two case studies illustrate losses caused by overloading semi-trailers.

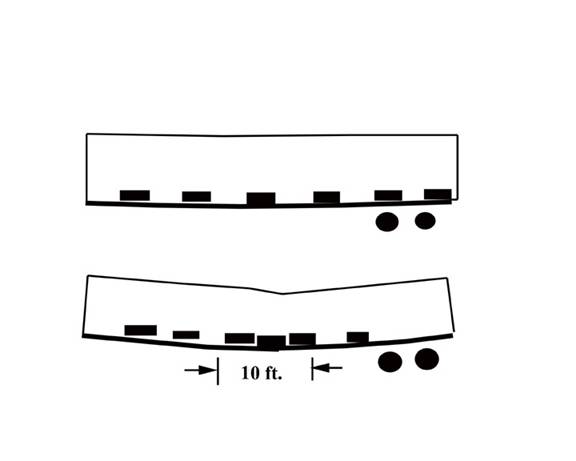

Figure 1 is a view of a typical van trailer that sustained a sidewall failure while carrying six pallets of copper wire, weighing approximately 7000 lbs each. The total load of 42,000 lbs in the trailer is acceptable, according to the manufacturer. The trailer manufacturer also stipulates that a maximum concentrated load of 15,000 lbs in 10 foot of trailer length should not be exceeded.

Figure 1

Figure 2

The upper drawing in Figure 2 shows the pallets, which were unsecured, in the approximate positions where they were placed on the trailer deck. While the trailer was traveling over the road in a highly vibratory environment, the pallets “walked” and tended to accumulate near the center as shown in the lower drawing. This resulted in concentrated floor loading, above that allowed by the trailer manufacturer, and buckling of the van trailer body. The failed trailer caused drivability difficulties and an accident. There was no evidence of a design or manufacturing defect in the trailer that could have caused the failure. The root cause of this loss is the lack of a means of securing pallets such that they did not move around during shipment.

Figure 3

Figure 3 is a photo of a

semi-trailer that ended up depositing its load on the highway, causing a

multiple vehicle accident and huge traffic disruption. Figure 4 shows severe

deformations to the aluminum deck of the trailer from the machinery load it was

carrying.

Figure 4

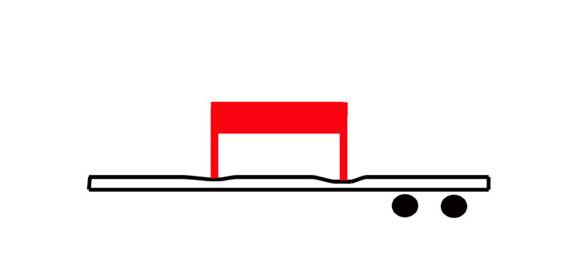

Figure 5

Figure 5 is a drawing of the machine secured to the semi-trailer with chain binders. Apparently, the machine feet overloaded the aluminum floor of the semi-trailer, causing the binders to slacken, dumping the load in the highway. Although the weight of the machine was within the capacity of the trailer, the concentrated foot loading on the aluminum deck overstressed and failed the deck. The trailer manufacturer gave no guidance on concentrated loading and relies on the person responsible for securing the load to provide bunkers or timbers to distribute the load. What is lacking here is guidance from the manufacturer regarding the maximum load per square foot capacity of the trailer. Relying on someone to guess at an acceptable weight distribution can lead to structural failure and a possible accident.

These two case studies illustrate the role weight distribution plays in safe cargo transport over the road. Those responsible for securing the load to a semi-trailer should consult user information provided by the manufacturer for proper weight distribution. Loads should be secured from “walking” during transport in order to avoid an improper weight distribution. Of the typical causes of structural failure of semi-trailers, improper cargo weight distribution related failure ranks high on the list and should be investigated when the potential of subrogation exists.