VEHICLE ACCIDENTS CAUSED

BY DEFECTS

Throttle Control System

By

Charles C. Roberts, Jr., Ph.D., P.E.

Vehicle

accidents can occur as a result of defects and are often at the root of an

insurance claim. It is not unusual for an insured to blame an automobile

accident on a defect related to a vehicle (my brakes failed, the accelerator

stuck, a tire detached, etc.) The claims analyst typically investigates the

existence of a defect in order to determine liability or the propensity of

subrogation. The extent of the many possible defects that may exist in an

automotive vehicle are numerous and beyond the scope of one article.† This is a first in a series of articles

dealing with vehicle defects that can cause an accident.† The subject matter of this article covers

case studies of actual accidents involving a defect in the throttle control system.

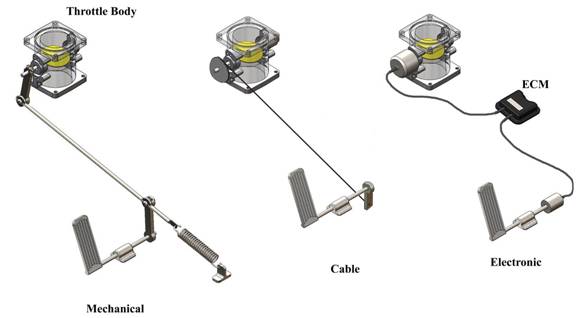

Figure

1 shows three typical throttle control systems in automotive vehicles. The

mechanical system is a classic, having been developed since the early days of

the automobile. Rod linkages are connected to the throttle plate to actuate the

throttle with a return spring whose purpose is to close the throttle plate once

the driverís foot is removed. The cable throttle control system is a more

recent design where a cable controls the throttle via a pulley. A torsional spring returns the throttle plate to a closed

position once the driverís foot is removed. The third system is a ďfly by wireĒ

or electronic control system where an accelerator position sensor sends a

signal to an electronic control module (ECM), that sends a signal to a throttle

position motor, which in turn sets the throttle position. †

Figure 1

The following case studies

illustrate problems with throttle control systems that have caused an accident.

A common throttle system malfunction is the engagement of the accelerator pedal

in the vehicle floor mat as shown in Figure 2 (upper photo). The driver of this

vehicle pressed the accelerator pedal to the floor, and when the pedal was released,

the vehicle continued to accelerate at high speed, eventually causing an

accident. There are several reasons for the engagement of an accelerator pedal

under a carpet. The carpet could be out of position, improperly installed, the

wrong size or improperly designed. Downloading the sensing diagnostic module

(black box) can show evidence of the malfunction.† In one instance, a dealer had substituted

another floor mat for the factory installed floor mat, causing the malfunction.

In another case, the insured supplied the floor mat. Clearly subrogation

potential is dependant on the claims analystís investigation tying down the

facts regarding the floor mat placement.†

†

†

Figure 2

Figure 2 (lower photo) shows an

accelerator pedal engaged in the polymer wear pad at a sewing seam. When the

accelerator pedal was pressed it readily engaged in the wear pad which resulted

in uncontrolled acceleration and an accident. †This is a design related defect.

Figure 3

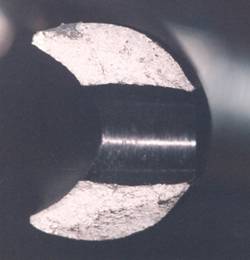

Another cause of throttle malfunction

is corrosion of throttle linkages. Figure 3 shows a small ball joint that is

part of a throttle assembly near the throttle plate. The ball joint eventually

became difficult to articulate due to corrosion, causing the throttle to remain

open after the accelerator pedal was released, which resulted in an accident.

In this particular case, corrosion resistive plating of the metal parts was

insufficient and was found to be a manufacturing defect.

† †

†

Figure 4

Figure

4 is a view of a hand throttle linkage that was part of a manual throttle system

used by disabled drivers. The linkage connected the accelerator pedal to a hand

lever that would operate the throttle. While driving the vehicle, the throttle

link failed, causing an accident. In the left photo of Figure 4 the arrow

points to a fracture that occurred at a bend in the linkage. The right photo

shows the fracture surface of the aluminum rod, with evidence of metal fatigue.

Apparently, the installer of the system had bent the aluminum rod in order to

facilitate installation, causing a crack that initiated a progressive failure scenario.

The bend occurred at a hole provided for bolts used to attach the rod to the

throttle system. †Metallurgical

examination determined that metal fatigue had reduced the rod cross section to

the point of failure. This is an installation related defect with subrogation

potential.

Electronic throttle control

systems are being designed into more recent vehicles and may become a more

prevalent throttle control system. Failure of electronic components may require

analysis of an event data recorder on the vehicle, which will often require a

manufacturer to download the data since the software is usually proprietary.

However, the mechanical parts of the electronic throttle control system can

exhibit failure modes similar to those shown in the case studies.

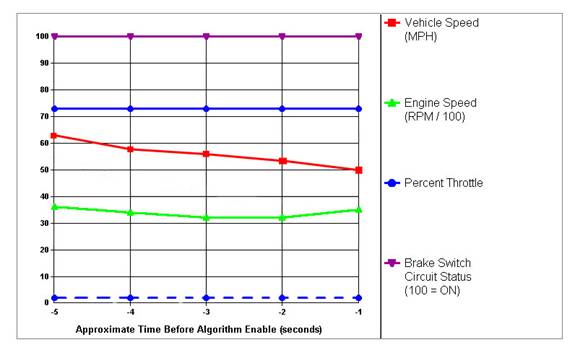

Figure 5 is a screen grab from

a crash data recorder download where a malfunction of the accelerator was

suspected. From 5 seconds to 1 second before impact, the throttle position was

constant at approximately 72% (solid blue line).† The brakes had been applied (lavender line)

and the vehicle was slowing from approximately 62 MPH, at 5 seconds before

impact, to 50 MPH at 1 second before impact. The engine was not at idle and

varied in RPM from 3200 to 3600 RPM. †With the driverís foot on the brake, the

percent throttle opening should decrease to near zero as indicated by the

dashed blue line. The data indicates that the throttle stuck in a position of

approximately 72%, which resulted in uncontrolled acceleration and an accident.

Figure 5

In

cases where throttle control failure is claimed or suspected, it would be

prudent for the claims analyst to inspect the vehicle to determine if evidence

suggests a malfunction that could result in recovery from a party to a legal

action. The evidence should be preserved for future inspection by various

experts, including those of the manufacturer.