Polymer Water Pipe Fitting Failures

By

Charles C. Roberts, Jr., Ph.D., P.E.

Acetal copolymers are

thermoplastics produced by the polymerization of aldehydes yielding unbranched

polyoxymetheylene chains. These materials have been used in the manufacture of

plumbing fittings for several years. Acetal resins are among the strongest and

stiffest of thermoplastics. They are easily molded into complex parts and are

relatively cost effective to manufacture. Unfortunately, over time, it has been

found that acetal fittings can fail as a result of environmental influences.

Figure 1 shows a failure of a water T fitting which caused a large loss at an

industrial facility. The body of the T fitting fractured at a stressed area

near a tube coupling. As usual, the fitting failed over a weekend and was not

discovered until the following Monday.

Figure 1

Figure 2

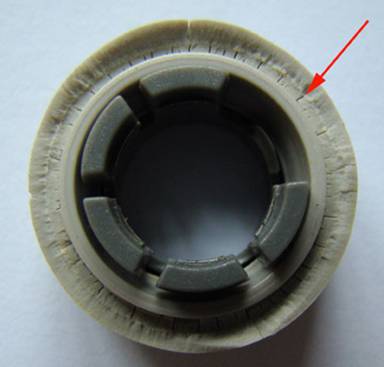

Figures 2 and 3 show views of

several cracks that had developed in the T fitting body. One of the cracks grew

sufficiently large, causing unstable crack growth and failure of the

fitting.

Figure 3

Acetal

copolymer has been found to be susceptible to aqueous solutions containing

hypochlorite ions (chlorine) at a level usually found in domestic drinking

water supplies. These oxidizing agents encourage environmentally assisted

cracking of the plumbing fitting, especially in areas of mechanical stress

concentration, such as threaded areas or sharp bends in the polymer. Additional

mechanical stress arises from the manufacturing process (molding) and

connection with other plumbing fixtures. High temperatures accelerate the

failure process. (A familiar similar phenomenon is the deterioration of

automobile tires. Oxygen atoms from the air cross-link with the long flexible

polymer chains making the tire outer surface much stiffer. When the tire

flexes, cracks form in the outer surface, eventually causing tire failure.)

The

cracking in the plumbing fitting shown in Figures 2 and 3 is typical of environmentally

related cracking. Chemical analysis of the

fracture surfaces revealed evidence of chlorine deposits. It was determined

that the chlorine atoms oxidized the polymer chains, causing chain cleavage

(separation of the polymer chain).

It

should be noted that some manufacturers are warning against using acetal fittings

in high chlorine concentration environments. Other manufacturers claim that

their acetal products are more resistant to chlorine. Material degradation of

acetal plumbing fittings in normal chlorinated environments can be considered a

design defect as a result of improper material selection. In some instances,

the product may contain several sharp features that result in high mechanical

stress concentration, which is an ingredient in environmentally assisted

cracking, also a design defect. Losses

from failures of acetal plumbing fittings are at the root of one of the largest

class actions in the