NTSB UPDATE ON THE MINNEAPOLIS BRIDGE FAILURE ANALYSIS

By

Charles C. Roberts, Jr., Ph.D., P.E.

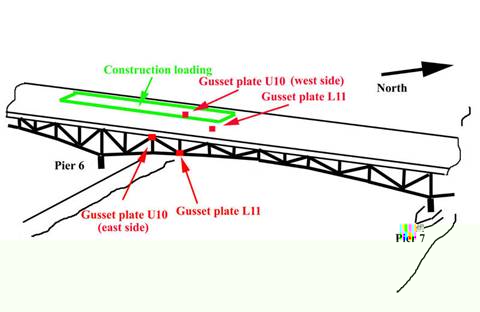

On January 15, 2008 the National Transportation Safety Board (NTSB) released an interim finding regarding the failure analysis of the I-35W bridge in Minneapolis. According to the report (1), investigators found that certain gusset plates that connect bridge structural members were under-designed according to American Association of State Highway Officials (AASHO) “Standard Specifications for Highway Bridges,” 1961. This resulted in several gusset plates installed with a ½ inch thickness instead of some larger thickness. Although the NTSB indicated that this was a design error, the chairman indicated that the federal probe into the bridge collapse is by no means final and that the cause has yet to be found. Figure 1 is a view of the bridge showing gusset plates U10 and L11, which the NTSB found to be the most severe violators of the AASHO standard and most deficiently designed. Figure 2 shows the approximate location of these plates in a post failure photograph.

Figure 1

Figure 2

It was also mentioned that approximately 300 tons of construction equipment was located over gusset plates U10 and U11 in the southbound lanes (green area Figure 1). According to the NTSB, all 16 of the under-designed gusset plates were found to be fractured while the remaining were typically intact. The original design calculations made by the bridge designers (Sverdrup and Parcel) could not be found. Accordingly, the NTSB could not determine how the apparent calculation error occurred. No deficiencies were found in the steel or concrete that could have caused a failure. The I-35W bridge was designed before 1964 and was completed in 1967 with additional dead (weight) loads added over time (1977 and 1998), which included a median barrier, larger outside walls and increased thickness of the concrete deck. According to the NTSB, this added significantly to the weight of the structure. No bridge design analyses could be found regarding the acceptability of the additional dead loads. At the close of the news conference, the NTSB emphasized that the investigation continues.

The conventional, post news conference, wisdom suggested that a design flaw in the structure was the cause of the collapse. This may be a premature conclusion because of the following:

- This bridge survived for a period of 40 years without collapsing. If the apparent design flaw was so influential in the collapse, then why did the structure not collapse sooner. The answer lies possibly in an understanding of what the AASHO “Standard Specification for Highway Bridges” means. It is essentially a calculation procedure with considerable safety margin to account for variability and uncertainties in design. For instance, axial tension is limited to 27,000 pounds per square inch (psi) in the gusset plates, yet the high-strength-low-alloy structural steel (HSLA) from which they are made has yield strengths of around 50,000 psi or higher. Gusset Plate U10 calculated axial tension was 39,500 psi (Reference 1), which is higher than that allowed (27,000 psi) but lower than the yield strength of the material. Despite the apparent design error, a safety margin still existed in the design of this gusset plate.

- The bridge has experienced two construction projects that have, according to the NTSB, added significant weight to the structure. Why didn’t the bridge collapse after the addition of these dead loads? The answer lies in the suggestion that despite the apparent design error, significant safety margin existed (that is built into the AASHO calculation procedures), and the bridge accommodated the additional loading.

- Corrosion has been evident throughout the bridge structure. Figure 3 is a view of corrosive pitting found at the L11 gusset during an inspection in June, 2006. (Reference 3) Gusset L11 was one of the gussets that was apparently under-designed according to the NTSB. Widespread cracking in the structure was found, much of it due to metal fatigue.

Figure 3

- Construction loads on the order of 300 tons dead load, plus vibratory loads, were applied in the southbound lanes, as shown in Figure 1 (green area) and were unsymmetrical in application (Reference 4). It should be noted that this loading was applied in the general area of gussets U10 and L11.

- Vehicle loading has increased significantly since the bridge was designed. In the mid 1970’s, weight limits on trucks were 50,000 lbs; now they are 80,000 lbs (In addition, some estimates indicate that 30% of trucks are overloaded).

- According to the NTSB, several of the apparently deficient gusset plates have fractured. If the failure origin of the structure is a gusset fracture that appears to have been initiated by a fatigue crack, then the apparent design error is almost irrelevant. The 1961 vintage AASHO specification is rooted in avoiding metal plastic deformation (yield strength) as a design criteria. Stable and unstable crack growth is a fracture mechanics phenomenon that was not a basis for the 1961 vintage AASHO standards.

Despite the apparent design error (the subject of the NTSB interim report) the safety margin designed into this bridge is remarkable in light of substantial increases in loading and long term deterioration (corrosion, metal fatigue) of the bridge structure over the past 40 years. To blame the collapse of the I-35W bridge on a design error made in the early 1960’s is, in my opinion, premature at this time.

References:

- “Adequacy of the U10 & L11 Gusset Plate Designs for the Minnesota Bridge No. 9340 (I-35W over the Mississippi River),” Federal Highway Administration, Turner-Fairbank Highway Research Center Report, Interim Report dated January 11, 2008, available on the internet at http://ntsb.gov/Recs/letters/2008/H08_1_Design_Adequacy_Report.pdf

- “Metal Fatigue,” Roberts, Charles Jr., Insurance Adjuster, March 1983.

- “Fracture Critical Bridge Inspection, Bridge # 9340, I-35W over the Mississippi River at Minneapolis, MN,” Minnesota Department of Transportation, June 2006.

- “Critical Failure – Insights and Analysis Into the Minneapolis Bridge Collapse,” Roberts, Charles Jr., Claims Magazine, September 2007, p32f.