WATER DAMAGE TO AUTOMOTIVE ENGINES:

HYDROSTATIC LOCK

By

Charles C. Roberts, Jr., Ph.D., P.E.

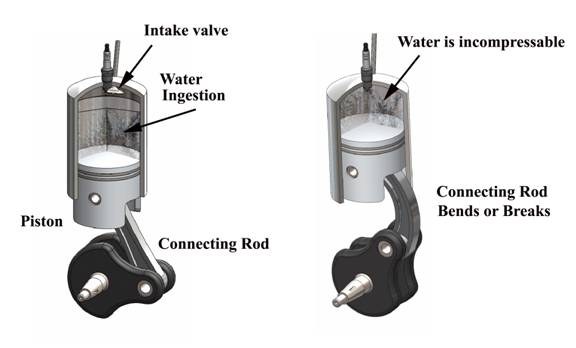

A specific type of

automotive engine damage occurs when water enters the engine and is compressed

in one or more cylinders. Figure 1

illustrates the damage sequence often called hydrostatic lock. The left drawing

in Figure 1 shows water entering a typical automotive engine cylinder during

the intake stroke. Water, unlike the fuel/air mixture, is incompressible and

during the compression stroke, locks the piston in place as shown in the drawing

at the right of Figure 1. This condition

tends to overload the connecting rod, causing a bending failure of the rod and

severe engine damage. A common way for water to enter the engine is driving

through water sufficiently deep to allow injecting into the air intake system

of the vehicle, such as crossing flooded roads.

Figure 1

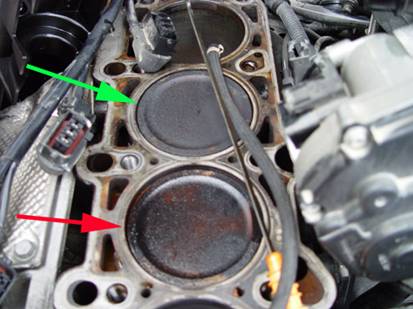

Figure 2

Figure 2 shows a failed

connecting rod that sustained hydrostatic lock. After stalling in a flooded

street, the vehicle operator started the engine, which suddenly failed. In this

case, the connecting rod bending failure resulted in a fracture through the

cross-section of the connecting rod. Figure 3 is a view of a connecting rod

that sustained a hydrostatic lock bending failure without a fracture.

Figure 3

Figure 4

Figure 4 shows an

engine that operated poorly after the owner drove through a flooded

street. The lower piston in the photo

(red arrow) should be at the same height as the upper piston (green arrow), but

is not. The lower piston is displaced downward relative to the upper piston,

suggesting that the connecting rod is shorter or bent as a result of

hydrostatic lock brought on by water ingestion into the engine.

Figure 5

Other evidence of

water ingestion into the engine may exist in the form of mud and water debris

patterns. Figure 5 shows a water damaged air filter, which is often damp and

crumbles when handled. Water marks on upholstery and carpeting in the occupant

compartment are additional clues that corroborate the assessment that water may

have entered the engine. Finally, an oil analysis2 may add further

information regarding the condition of the engine. If wear metal analysis

yields evidence of long term related engine damage, then it is possible that the

engine failure was not related to hydrostatic lock, absent any other evidence

as exemplified in Figures 2 through 5. It should be noted that some engine failure

modes such as connecting rod bearing wear-out2 can cause connecting

rod failure, which is not related to hydrostatic lock.

References:

- Roberts, Charles Jr., "Motor

Vehicle Accidents Caused by Mechanical Failures," Claims Magazine,

January 1988, p33f.

- Roberts, Charles Jr., "Engine Oil

Analysis," Claims Magazine, February 1990, p58.

- Roberts, Charles Jr., "Truck

Component Failure Analysis," Claims Magazine, August 1996, p64f.

- Roberts, Charles Jr., “Throttle

Mechanism Failure Analysis,” Claims Magazine, May 2001.