FAILURE OF A TWO CENT FASTENER CAUSES

MILLION DOLLAR LOSS

By

Charles C. Roberts, Jr., Ph.D., P.E.

Figure 1 is a photo of a large supermarket that was nearly completely destroyed by a fire. According to the employees at the supermarket, the fryer in the delicatessen was turned on to get warmed up for the day’s cooking. Shortly afterward, the fryer apparently overheated, expelling hot grease which ignited and started the fire that caused a million dollars in damage. Fire origin analysis confirmed the fryer as the offending unit and it was removed for forensic analysis.

Figure 1

Figure 2

Figure 2 is a top view of the fryer showing two baskets, the pan containing the grease and the control system to the right. The power switch was found to be on, supplying electrical power for the heating elements in the unit.

Figure 3

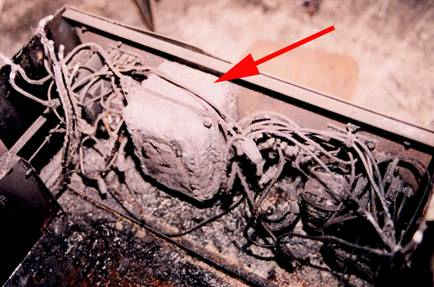

Figure 3 shows the electrical control system with the arrow pointing to the enclosure containing the contactor, which controls power to the electric heaters.

Figure 4

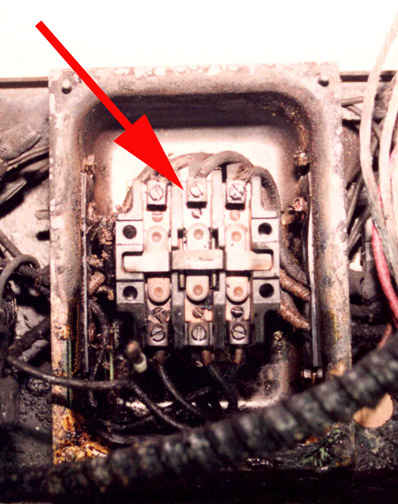

Figure 4 shows the contactor inside the enclosure as indicated by the arrow. Electrical measurement showed the contactor to still be closed. Normally, when the thermostat indicates the cooking temperature has been reached, the thermostat opens and the contactor interrupts power to the heaters. The thermostat worked properly, but the contactor appeared to be jammed in the closed position.

Figure 5

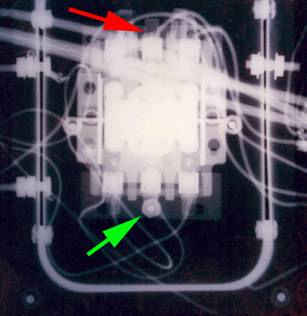

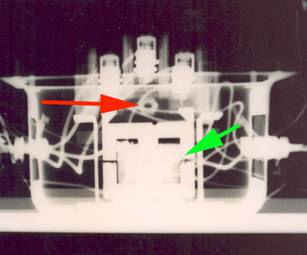

While inspecting the contactor to determine why it was jammed closed, a small 8-32 hex nut fell out of the contactor. The contactor then operated properly. Prior to the inspection, X-Rays were taken of the unit. Figure 5 shows a frontal X-Ray view of the contactor in the enclosure. The green arrow shows a mounting hex nut at the bottom flange of the contactor (lower, green arrow). The nut securing the top part of the mounting flange is missing as indicated by the red arrow. Figure 6 is a side view X-Ray of the contactor. The green arrow shows the contactor armature, while the red arrow shows the missing nut jammed into the contactor, preventing it from opening.

Figure 6

Figure 7

Figure 7 shows the stud on the upper flange of the contactor with the hex nut missing. Apparently the hex nut had loosened, backed out and fallen into the contactor, jamming the contactor closed. When the thermostat was satisfied, it dropped control power to the contactor, but the contactor remained closed as a result of the interference of the mounting hex nut. The fryer then overheated, causing the fire.

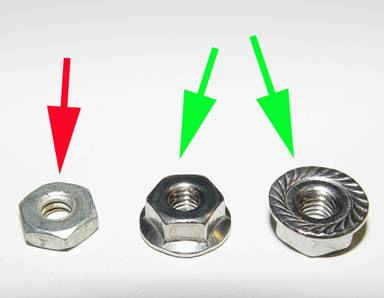

Figure 8

Prior to the fire the contactor had been replaced. Plain hex nuts (red arrow, Figure 8) were used to secure the contactor to the mounting plate instead of the original serrated-flange nuts (green arrows, Figure 8). Due to equipment vibration and thermal cycling, the plain hex nut easily backed off, causing the failure. The serrated-flange nuts have greater gripping capacity and perform well when used on oversized holes, as was this application. Lack of diligence in reinstalling the proper two cent fastener lead to the million dollar fire loss.