ANALYSIS OF A WATER PIPE

COMPRESSION FITTING FAILURE

By

Charles C. Roberts, Jr., Ph.D., P.E.

Figure 1 is a view of a typical plumbing compression

fitting used to splice plumbing pipes. In some installations with long pipes

and limited access, replacement of a section of pipe is often accomplished with

two compression couplings at each end of the replacement pipe.

Figure 1

Figure 2

Care in the installation of compression couplings

should be exercised as illustrated in the following case study. Plumbers

repaired a pipe that was leaking, as a result of corrosion, on the third floor

in an old, historic building. A section of the pipe was removed and replaced

along with two compression couplings, one at each end. The plumbers finished

the work and left. Approximately 3 days later, one of the compression fittings parted,

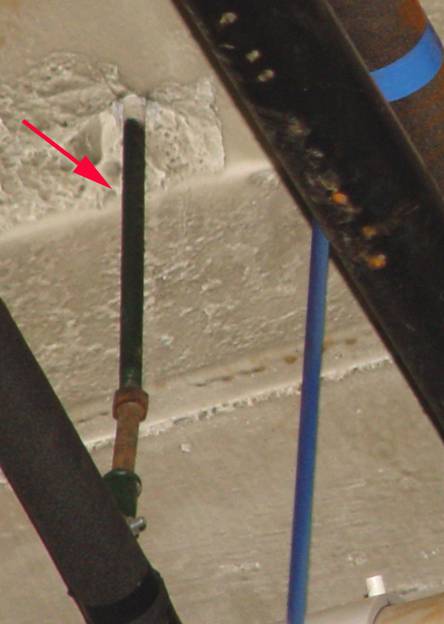

causing a significant water loss. Figure 2 (arrow) shows the pipe that had

parted from the compression fitting.

Figure 3

Figure 3 shows the parted pipe and the outline of the

compressed rubber seal of the compression fitting. The compression fitting

worked its way off the end of the pipe, allowing water to pour down several

floors of the building.

Figure 4

Further inspection of the vertical pipe in the

basement yields a clue to the failure of the coupling (Figure 4). The vertical pipe that pulled loose of the

coupling (arrow, Figure 4) terminated at a T fitting with a larger pipe. The

hangers of the larger pipe had deteriorated, rendering the large pipe virtually

unsupported other than the support of the vertical pipe that failed. The

friction of the vertical pipe through the concrete floors and the deteriorated

pipe hangers were the only restraint holding the large horizontal pipe in

place.

Figure 5

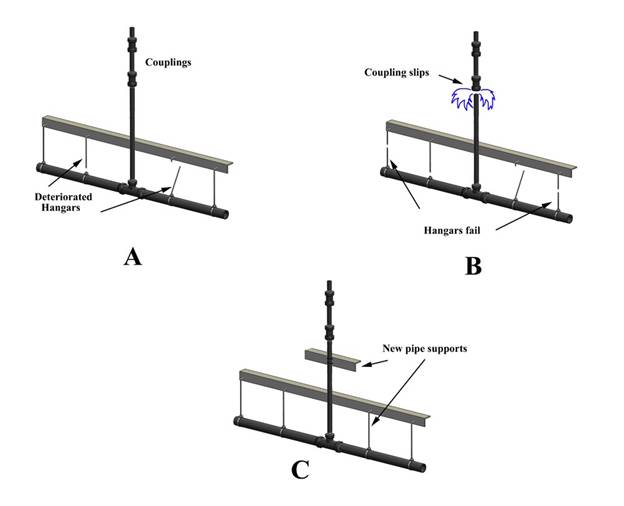

Figure 5 illustrates the failure scenario. Figure 5A

shows the system with the coupling in place, shortly after the plumbers had

left the job site. Figure 5B shows that the vertical load carrying capacity of

the pipe has been significantly reduced with the usage of the compression

fitting. Because of the limited axial force capacity of the vertical pipe when

using compression fittings, the deteriorated hangars failed, shifting the load

to the vertical pipe and couplings. The couplings could not support the load,

slipped and parted. It should be noted that compression fittings require

restraints against axial movement brought on by weight and vibration related

forces. Unlike threaded fittings,

compression fittings can seal properly but still slip out of position as a

result of forces on a pipe. In this case, the plumbers failed to properly

restrain the repaired pipe when using compression fittings. Figure 5C shows

that a restraint for the vertical pipe and hangar repair should have been

performed before job completion. A quick inspection of the pipe in the basement

would have revealed the necessity to repair the pipe hangers and restrain the

repaired pipe. No defects were noted in the compression fittings that could

have caused the failure. Analysis of the evidence suggests that the underlying

cause of the failure was improper repair of a water pipe.