The Physical Designer’s Nightmare:

Chaffing of Electrical Wire Insulation

By

Charles C. Roberts, Jr., Ph. D., P.E.

The

design of electronic equipment takes place through the efforts of circuit

designers who develop the parameters for an electronic system, and physical

designers who deal with the layout of the electronic equipment. The physical

design of wiring systems is an important aspect of their development. Choice of

wire type, wire layout, wire supporting means, and wire restraints are typical

design parameters used in the physical design of electrical equipment. An

important part of this design process is the phenomenon of electrical wire

insulation failure, as a result of chaffing.

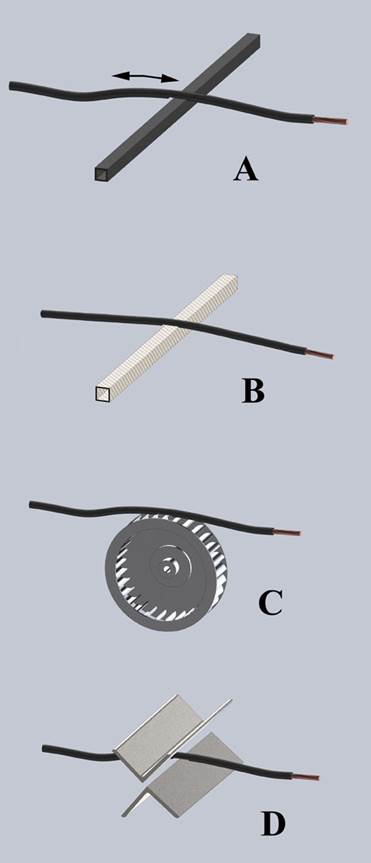

Chaffing is the wearing of electrical wire insulation by a variety of

means, as shown in Figure 1.

Figure

1A shows classical vibratory wear of wire. Here, the designer has allowed the

wire to rest on a surface that vibrates, causing insulation breakdown and

eventually an electrical fault; assuming that the surface is at a different

electrical potential, which is likely the case. In Figure 1B, a wire is routed

over an abrading surface and is chaffed from thermal expansion and contraction

as a result of environmental thermal effects as well as resistive heating when

the electrical system is active. Figure 1C shows a mechanical device whose

surface moves relative to the wire insulation, causing chaffing. Figure 1D

shows pinching of the wire, causing insulation breakdown often accelerated by

high temperatures and tensile loads in the wire.

In order to illustrate

typical chaffing problems, the following is a sampling of wiring malfunctions

brought on by chaffing.

Figure 1

Figure 2

Figure 2 shows a fan system

with a fire origin (arrow) at control wiring lying against a sheet metal

support bracket. Wire chaffing has occurred, developing an electrical fault and

causing the fire. In many instances, the fuse or breaker would interrupt the

circuit, stopping any further damage to the device. In other instances, the

electrical fault may have sufficient resistance to limit current and not blow a

fuse or trip a breaker. It should be noted that energy dissipation density at

the fault area causes the fire, not only the amount of electrical current. A relatively small current driving a fault

through a very small area can cause high temperatures and ignite combustible

material, resulting in a fire and significant damage.

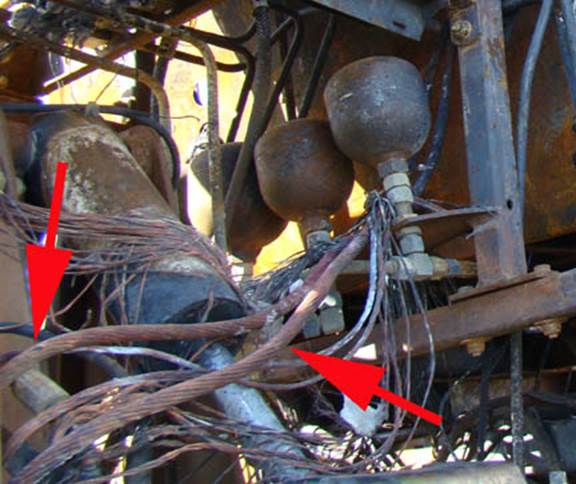

Figure 3

Figure 3 depicts an unfused

battery wire that was chaffing against an hydraulic

line in a large vehicle. The wire chaffed, faulted against the hydraulic tube and

formed a penetration through the tubing wall, in a manner similar to electric

discharge machining (EDM). The resulting hydraulic fluid pressure release

caused a spray of hydraulic fluid, which was ignited, destroying the

vehicle.

Figure 4

Figure 4 shows the remains of

an engine block heater cord located at the front bumper of a pickup truck. It

is not unusual for vehicle owners to back out of the garage without unplugging

the cord. Chaffing occurs quite readily, which caused an electrical fault, a

fire and total destruction of the vehicle and garage.

Figure 5

Figure 5 is a view of a battery

wire that faulted against an engine mount near the exhaust pipe on a large

truck. Vibration and softening of the electrical insulation from exhaust pipe

heating resulted in an electrical fault, which ignited combustible material and

destroyed the vehicle.

Figure 6

Figure 6 is an example of

mechanical interference with wiring. A bell crank for a heater vent in an

automobile was moving back and forth under normal usage, chaffing the wiring

harness that eventually faulted, causing a fire and destruction of the

vehicle.

Figure 7

When analyzing the remains of

equipment, an item that tends to attract one’s interest is the existence of

non-factory related modifications.

Figure 7 depicts a non-factory related connection to a battery post.

Following this add on wire, which lead to the point of origin of the fire,

verified an unsecured condition that was subject to vibration and consequent chaffing.

Figure 8

Wiring bundles or harnesses

have their own set of problems. In Figure 8, a power wire in the wiring harness

faulted, causing severe damage to a piece of equipment. Thermal expansion and

contraction from electric current in the power wire inside the harness caused

chaffing and an electrical fault.

Figure 9

In Figure 9, power wires

(arrows) are draped over various parts of a vehicle, a poor physical wiring

design. One of the wires chaffed, faulted, and the vehicle was destroyed by

fire. A more organized physical design of wiring, along with appropriate stand

off clamps, would have prevented this failure.

These case studies serve to

illustrate many physical wiring design deficiencies that caused severe damage

to equipment. Some design related tenants come to mind:

1. In the absence of a vibratory environment, cyclic

movement from thermal expansion and contraction can still occur, causing

chaffing. Leave an appropriate amount of wire slack to avoid wire tension

during thermal contraction (Figure 1B).

2. Interference of electrical wiring with mechanical

apparatus is a cause of chaffing requiring proper routing and restraint (Figure

1C).

3. In vibratory environments, usage of cable clamps and

other restraining devices should be considered as part of the design. Avoid

laying cables randomly over a machine (Figure 9) and relying on the quality of

the insulation to prevent a malfunction.

4. Attention should be paid to wire bundles that contain a

mixture of low current and high current wiring. Thermal cycling can cause

relative movement between wires in a bundle or harness. Also, different types

of wire insulation can aggravate chaffing from relative movements. Finally,

routing wiring horizontally, rather than vertically, may limit damage to

equipment as a result of a fault.

Vertical wiring harnesses burn more readily than horizontal wiring

harnesses since convective forces drive combustion gases vertically, easily

increasing the chance of fire development.

5. Avoid routing wires in high personnel traffic areas

such as under carpets. Avoid having wiring harnesses routed in an area where it

is convenient to be used as a hand hold device during maintenance or other

activity.

6. When using stand off clamps or other means of restraint, care should be taken not to pinch individual

wires in a bundle, when securing the clamp.

7. Particulates, such as metallic debris, should not be

in the vicinity of wiring harnesses since the debris can accelerate chaffing as

a result of thermal expansion and vibratory means.

Many

references are available on physical design of wiring, examples of which are:

1.

Aircraft

Electrical Wiring Interconnect System Best Practices, Federal Aviation

Administration, Revision 2.

2.

Society of

Automotive Engineers Standards on Wiring.

3.

National Electric

Code.

Published in Machine Design 2014