CAPACITOR FAILURES CAN CAUSE

FIRES AND EXPLOSIONS

By

Charles C.

Roberts, Jr.

Ph.D., P.E.

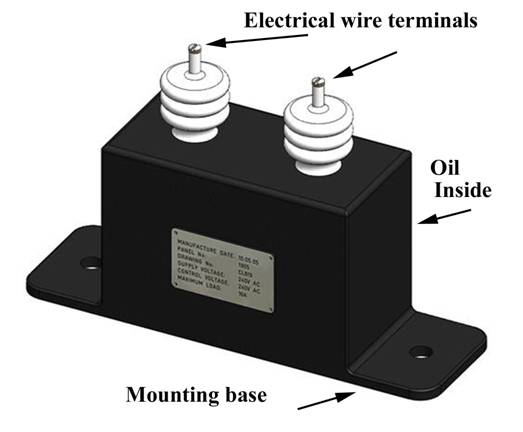

Oil filled capacitors are electrical

components that store electrical energy and are used in a wide variety of

electrical applications. Figure 1 is a view of a typical oil filled capacitor.

The two terminals on top are for wire connections. The device is often bolted

to an electrical chassis via the mounting base. The housing contains the

capacitor surfaces and a dielectric oil, which is used

to increase the dielectric strength of the gap between the capacitor plates and

reduce undesirable electrical discharges (corona discharge). The dielectric oil

inside can range from PCB based materials to silicone oils. Typical oils are

castor oil, canola oil, mineral oil, ethyl hexyl phthalate, phenyl xylyl

ethane, isopropyl biphenyl and polydimethyl siloxane. Failure

of oil filled capacitors can occur, resulting in ignition of the dielectric

fluid and causing a fire or explosion.

|

|

|

Figure 1 |

|

|

|

Figure 2 |

A case study involving an incident where a capacitor

failure damaged a small building serves to illustrate the consequences of oil

filled capacitor failure. Figures 2 and 3 are views of a small block wall

building that was a shelter for a radio transmitter. The transmitter suddenly

quit operating and the radio station went off the air. Investigators found the

walls of the building pushed out as indicated by the arrows in Figure 2. The

damage was consistent with slight internal pressure inside the building,

similar to that of a low energy explosion. Figure 3 shows slight overpressure

damage near a ventilation duct as indicated by the arrow.

|

|

|

Figure 3 |

|

Figure 4 |

Further investigation revealed thermal damage to the

inside of an electronic cabinet depicted in Figure 4. Using thermal damage

patterns as a guide, a failed capacitor, which had been badly damaged, was

found in the electronic cabinet (Figure 5). The arrow in Figure 5 points to an

oil leakage pattern originating from an oil filled

capacitor. There was evidence of oil

leakage (arrow) from the capacitor, allowing air to fill the void inside. As

the capacitor plates become exposed to the air, the dielectric strength of the

plate gap decreases, causing a sudden high energy electrical discharge between

plates. This discharge has sufficient energy to ignite oil vapor and cause an

explosion, albeit a small one.

|

|

|

Figure 5 |

Capacitor failure, such as that previously described,

can occur for a variety of reasons. They are defective manufacture, defective

design, improper installation, shipping damage or an

intervening biologic. Defective manufacture includes not enough fluid in the

capacitor, insufficient plate gap or improper sealing of the capacitor housing.

Defective design includes improper electrical specification (using the unit at

an excessive voltage) or insufficient cooling of the electronic equipment. Examples

of improper installation are excessive strain on the capacitor housing from

mounting or deforming the unit during installation. Damage to the capacitor

case can result in plate gap reduction that can cause a discharge and capacitor

failure. Finally, an intervening cause such as a rodent (biologic) contacting

the two electrodes simultaneously will likely cause a capacitor failure.