Anti-friction bearings which include ball, roller and needle bearings are used in many industrial and consumer product applications. Automobiles, industrial machinery, household appliances and aircraft are examples of mechanical apparatus that rely on anti-friction bearings for proper function.

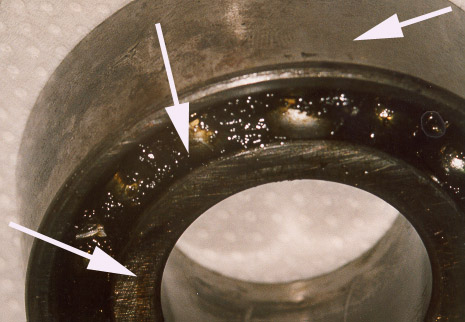

Figure 1

Figure 1 is a view of a typical ball bearing. The arrow to the upper right points to the outer race, essentially an outer track that directs the rolling action of the balls. The arrow to the left of Figure 1 points to the inner race that is the inner track of the assembly and also typically connects to a shaft. The center arrow points to the retainer or cage which provides equal spacing for the bearing balls.

Figure 2

Figure 2 is an example of a loss involving an anti-friction bearing, in this case a roller bearing, in the axle of a motor home. The insured was driving the vehicle at highway speeds when one of the axle bearings failed, causing excessive heating and ignition of the motor home structure, resulting in a total loss of the vehicle and contents.

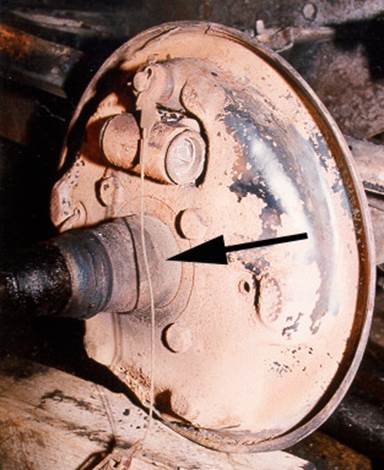

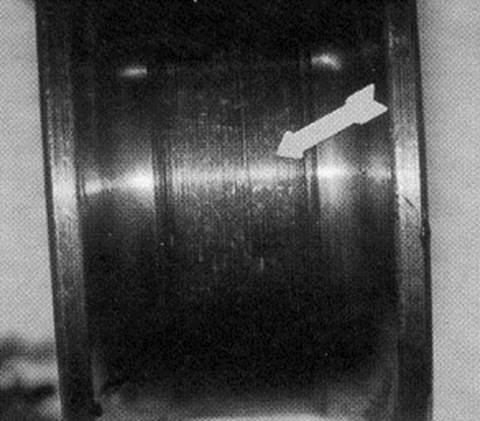

Figure 3

Figure 3 shows the axle shaft supporting the bearing that failed.

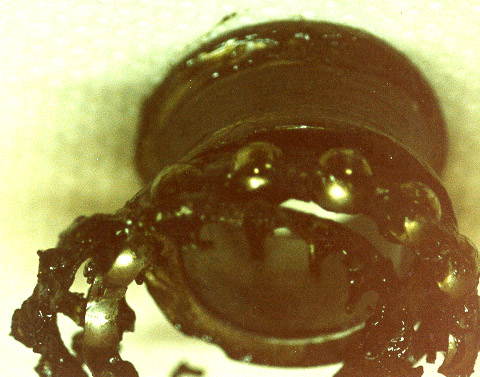

Figure 4

Figure 4 shows the wheel drum and the remains of the roller bearing retainer or cage as indicated by the arrow. When the bearing failed, the wheel drum began dragging on the brake shoes, resulting in excessive heating and fracture of the wheel drum. Red hot drum fragments were thrown into the vehicle structure causing the fire. Improper preload of the bearing (tightening of the axle nut) is the suspected cause of the failure.

Typical failure symptoms of anti-friction bearings include corrosion, seizing, race flaking, retainer failure, electrical erosion, brinelling and fretting:

Corrosion is typically a result of improper storage, poor maintenance or insufficient rust inhibitor.

Seizing is a result of overloading, improper preload, inadequate lubrication or improper lubricant.

Race flaking (rapid metal fatigue of bearing surfaces) is a result of improper installation, misalignment, vibration, contamination of lubricant and overloading.

Retainer failure (cage failure) is often a result of contamination, improper lubrication or excessive speed.

Electrical erosion happens when electrical currents travel though bearings, causing arcing as the bearing surfaces bounce against each other.

Brinelling is a result of excessive forces placed on a bearing in a static mode such as when a piece of machinery has been dropped. Small dents in bearing surfaces are a result.

Fretting is the rubbing of bearing surfaces causing oxidation of the surfaces in a manner similar to brinelling.

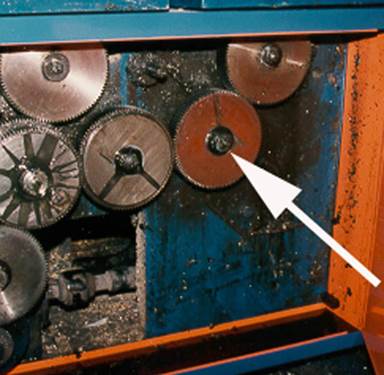

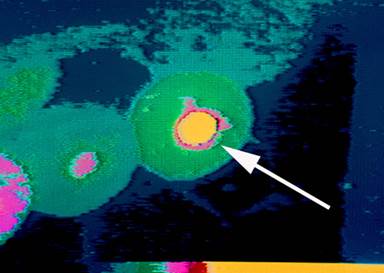

Figure 5

Figure 6

Figure 5 is a view of a bearing used to support a drive gear shaft on a high speed printing press. Infrared thermography (Figure 6) shows significant heating of the bearing, a leading indicator of a failure.

Many of the previously mentioned failure modes manifest themselves in overheating. Figure 7 is an example of retainer (cage) failure from contaminated lubricant.

Figure 7

Figure 8

Figure 8 shows a pitted inner bearing surface resulting from excessive vibration. Figure 9 is an example of seizing as a result of improper lubrication.

Figure 9

Bearing failures are typically a result of poor maintenance, improper manufacture or improper design. Vandalism resulting in a bearing failure is also a possible cause. Information from the insured regarding the particular maintenance performed on the machinery in question helps distinguish between manufacturing and maintenance deficiencies. Oil samples or grease samples should be analyzed for contaminants and metallic content. Preserve the bearing for failure analysis, especially when improper design or manufacture is suspected. Finally, inquire as to any modifications or unusual operating procedures that may violate warranties and manufacturer's instructions.

__________________________________________________________

Charles C. Roberts, Jr. PhD. is a registered professional engineer at C. Roberts Consulting Engineers, Inc., Rochelle IL 61068 and may be reached at 877/556-3039 or CCR@croberts.com