Every year, hundreds of parks, carnivals and fairs operate a variety of amusement rides throughout the United States. Amusement rides often provide a level of dynamic forces leading to the well known thrill most of us enjoy.

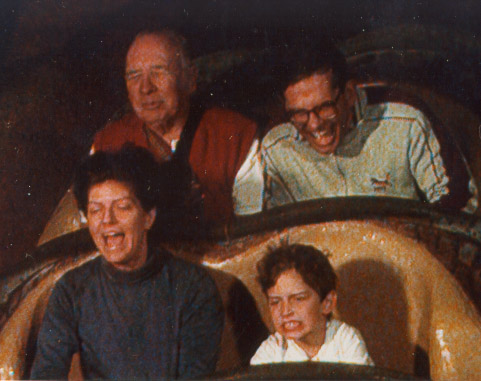

Figure 1

Figure 1 shows riders on a typical roller coaster during the nearly "free fall" phase where the occupants experience the semi-nauseous feeling of zero gravity. Amusement ride designers tend to engineer rides such that the occupants experience a range of forces from near weightlessness to over 2G or twice one's body weight. Consequently, amusement ride structures are designed to relatively high safety margins to accommodate the force environment and public safety requirements. Despite thorough design practices by manufacturers and rigorous inspection by state authorities, accidents do occur. Typical accident scenarios revolve around abuse of the ride, not following directions, improper maintenance, and improper design.

Figure 2

Figure 2 is a view of a car that became detached from a ride, resulting in a fatality. The car was originally suspended from the ride structure by steel cables. The main support structure would rotate and the cars would tend to swing out via centrifugal force. Since the steel cables were deteriorating, the ride owner replaced them with a chain and crimp link attachment to the lugs on the car as shown in Figure 3.

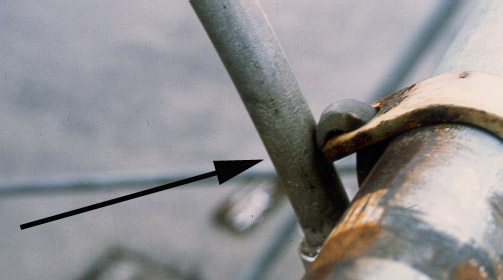

Figure 3

No load testing was performed on this "redesign.” The following weekend, the ride was first used with the modification and a rider was killed when the car became detached. The crimp links attached to the car lugs deformed as shown in Figure 3 and were obviously not capable of carrying the loads associated with the ride.

Figure 4

Figure 4 is a view of a failed support cable for an amusement ride. The cable failed during the deployment of a ride, causing a section of the ride to descend and strike one of the operators, resulting in severe injury. The cable failure analysis revealed severe repeated bending as a cause of the failure. The severe bending area on the cable was at a small sheave located on the ride. The sheave was too small for the particular wire rope diameter. Prudent design of cable systems requires exceeding minimum diameter sheave sizes to prevent bending damage to the wire rope. In this case, a design deficiency (sizing the sheave below minimum requirements) was the ultimate cause of the failure.

Figure 5

Figure 5 is a view of a slide where a rider mounts a water sled, slides down the slide and planes across a pool of water until speed dissipates and the ride is ended. An older person with documented chronic back pain rode the ride and claimed her condition to be aggravated by the ride. Testing of the ride showed moderate G-loading on a person using the ride, not unusual for such rides. In this case, the rider exercised poor judgment by riding on an amusement ride with a medical condition that could be aggravated by moderate G-loading.

Figure 6

Figure 6 is a view of a swing set that is partially disassembled for inspection purposes. A child was propelled off the swing and sustained a severe back injury. The child indicated that a sudden "jerk" in the swing caused her to fall from the swing. Examination of the swing revealed impact marks on the swing support bracket shown in Figure 7. Apparently the swing was "over swung," causing the swing frame to impact on the brackets, causing sudden stoppage of the swing, consistent with a "jerking" motion. The child had been cautioned not to "over-swing" the swing, an apparent abuse of the swing set. Amusement ride related accidents, although rare, do occur and are known to cause significant injuries or fatalities.

Figure 7

When analyzing such accidents, the state accident report is a source of information. Most states have agencies that are charged with the responsibility of overseeing safety on amusement rides. Medical records can yield information as to how the accident occurred. As always, damaged parts should be preserved for future analysis to aid in causal determination. Avoid spoliation claims by properly preserving and storing evidence.

Charles C. Roberts, Jr. PhD. is a registered professional engineer at C. Roberts Consulting Engineers, Inc., Rochelle IL 61068 and may be reached at 877-556-3039 or CCR@croberts.com.